For OMRON MS / MS4800 Series Safety Light Curtain Replacement Basic Type 30 mm Resolution | 20 m Operating Range | 360 mm to 2040 mm Protective Height

- Model

- MS4800 Series | MS4800B-40-0360, MS4800B-40-0480, MS4800B-40-0600, MS4800B-40-0720, MS4800B-40-0840, MS4800B-40-0960, MS4800B-40-1080, MS4800B-40-1200, MS4800B-40-1320, MS4800B-40-1440, MS4800B-40-1560, MS4800B-40-1680, MS4800B-40-1800, MS4800B-40-1920, MS4800B-40-2040

Item specifics

- Series:

- MS4800 Series

- Resolution:

- 30 mm

- Scanning range:

- 0.3 m - 20 m

- Protective field height:

- 360 mm - 2040 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 23 ms

- Connection type:

- M12

- Security level:

- PLe4

Review

Description

For OMRON MS4800 Series Safety Light Curtain Replacement Parameter

Brand | From network | DADISICK |

|

|

Models

|

MS4800B-40-0360 | QT10-40-360-2BE |

|

MS4800B-40-0480 | QT12-40-440-2BE | ||

MS4800B-40-0600 |

QT16-40-600-2BE | ||

MS4800B-40-0720 | QT18-40-680-2BE | ||

MS4800B-40-0840 | QT22-40-840-2BE | ||

MS4800B-40-0960 | QT24-40-920-2BE | ||

MS4800B-40-1080 | QT28-40-1080-2BE | ||

MS4800B-40-1200 | QT30-40-1160-2BE | ||

MS4800B-40-1320 | QT34-40-1320-2BE | ||

MS4800B-40-1440 | QT36-40-1400-2BE | ||

MS4800B-40-1560 | QT40-40-1560-2BE | ||

MS4800B-40-1680 | QT42-40-1640-2BE | ||

MS4800B-40-1800 | QT46-40-1800-2BE | ||

MS4800B-40-1920 | QT48-40-1880-2BE | ||

MS4800B-40-2040 | QT52-40-2040-2BE | ||

Beam spacing | 30 mm | 40 mm | |

Protected altitude | 360 mm, 480 mm, 600 mm, 720 mm, 840 mm, 960 mm, 1080 mm, 1200 mm, 1320 mm, 1440 mm, 1560 mm, 1680 mm, 1800 mm, 1920 mm, 2040 mm | 360 mm, 440 mm, 600 mm, 680 mm, 840 mm, 920 mm, 1080 mm, 1160 mm, 1320 mm, 1400 mm, 1560 mm, 1640 mm, 1800 mm, 1880 mm, 2040 mm | |

Scanning range | 0.3 m - 20 m | 0.3 m - 20 m | |

Response time | 23 ms | ≤15 ms | |

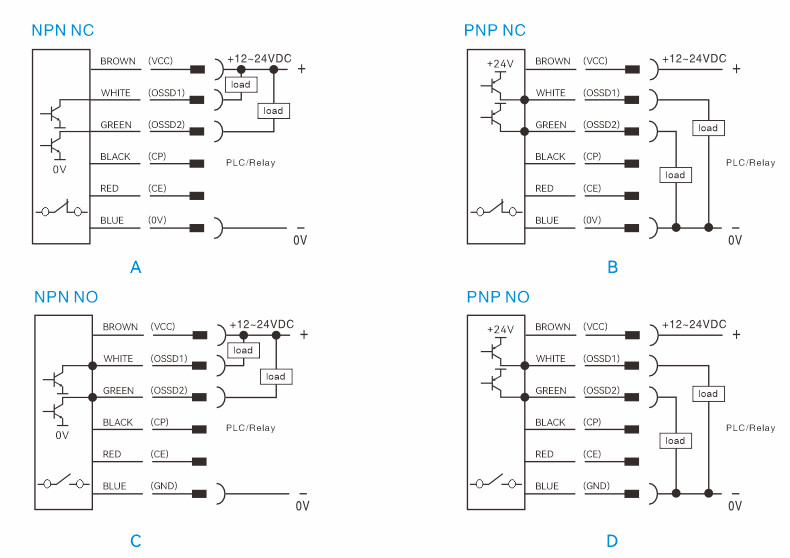

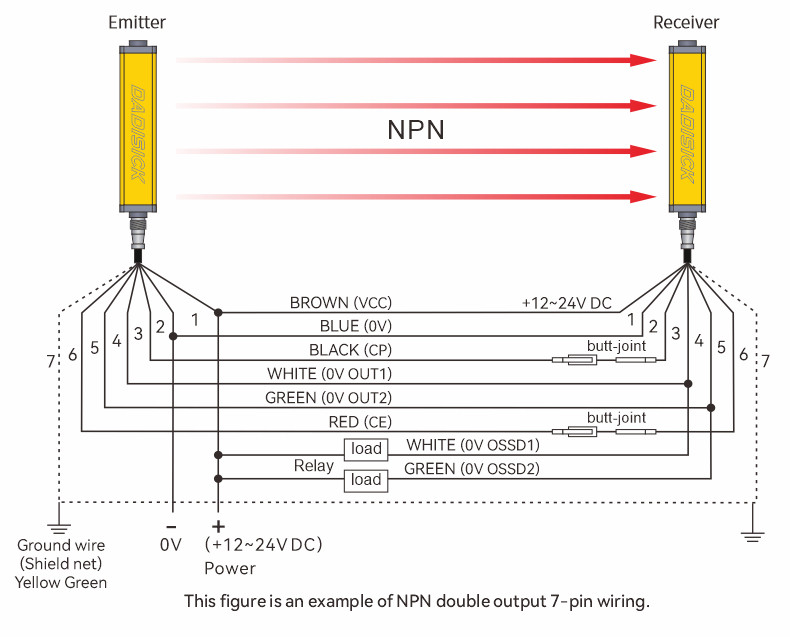

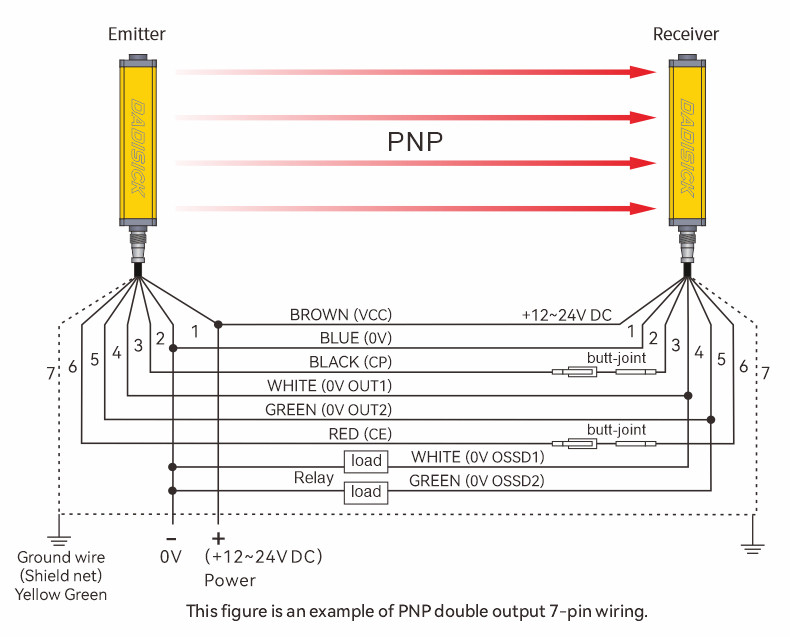

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

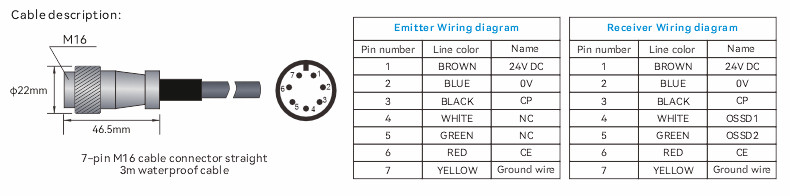

Connector | M12 | M16 | |

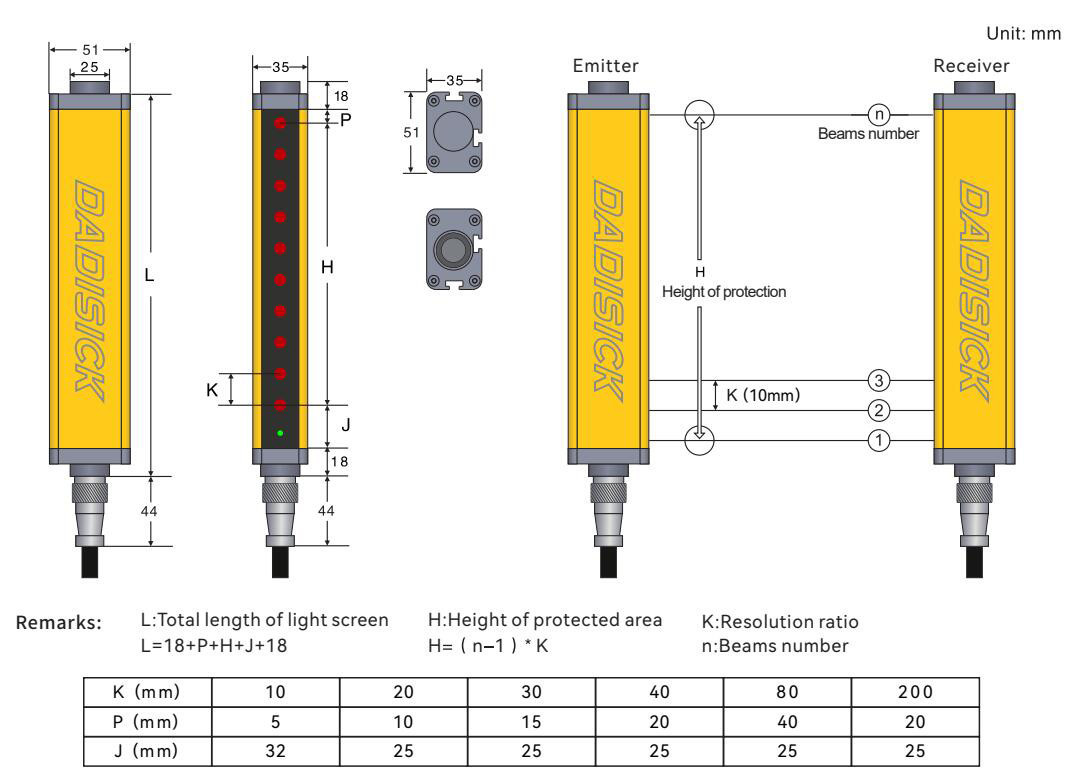

Housing cross-section | 38 mm × 53.6 mm | 35 mm × 51 mm | |

Safety Certificate | CE, TÜV, UL, S-Mark | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand OMRON's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QT10-40-360-2BE, QT12-40-440-2BE, QT16-40-600-2BE, QT18-40-680-2BE, QT22-40-840-2BE, QT24-40-920-2BE, QT28-40-1080-2BE, QT30-40-1160-2BE, QT34-40-1320-2BE, QT36-40-1400-2BE, QT40-40-1560-2BE, QT42-40-1640-2BE, QT46-40-1800-2BE, QT48-40-1880-2BE, QT52-40-2040-2BE

FAQ

How do safety light curtains prevent guard gaps?

Safety light curtains prevent guard gaps in several ways:

1.Continuous Detection Zone: Safety light curtains create a continuous detection zone using multiple infrared beams. This zone is adjustable in height and width to cover the entire area that needs to be guarded.

2.No Dead Zones: Unlike other guarding devices, safety light curtains do not have dead zones where objects can pass undetected. The multiple beams ensure that any object, regardless of its size, shape, or orientation, will be detected if it passes through the light curtain.

3.Adjustable Resolution: The resolution of the safety light curtain, which determines the spacing between individual beams, can be adjusted. By reducing the beam spacing, a finer detection zone can be created, effectively eliminating small gaps that could allow objects to pass undetected.

4.Rapid Response Time: Safety light curtains have a very fast response time, typically in milliseconds. This means that as soon as an object interrupts one or more beams, the safety light curtain will immediately send a signal to stop the hazardous machine movement.

5.Redundancy: Many safety light curtain systems feature redundancy, meaning they have multiple layers of detection. If one beam is interrupted, the system will not necessarily stop the machine, but if multiple beams are interrupted, indicating a larger object, the system will trigger an emergency stop.

6.Monitoring and Diagnostics: Modern safety light curtain systems often include monitoring and diagnostic features that can detect when a beam is malfunctioning or if there is a gap in the detection zone. This allows for prompt maintenance and repair, ensuring the system's continued effectiveness.

By creating a continuous and adjustable detection zone with no dead zones, safety light curtains effectively prevent guard gaps, making them an effective safety solution for many industrial applications.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.