For Pilz PSENopt Series 30 mm Resolution 19 m Sensing Distance 150 mm to 1800 mm Protective Height Basic Type 4 Light Curtain with Hand Protection Replacement

- Model

- PSENopt Series | PSEN op4H-s-30-015/1, PSEN op4H-s-30-030/1, PSEN op4H-s-30-045/1, PSEN op4H-s-30-060/1, PSEN op4H-s-30-075/1, PSEN op4H-s-30-090/1, PSEN op4H-s-30-105/1, PSEN op4H-s-30-120/1, PSEN op4H-s-30-135/1, PSEN op4H-s-30-150/1, PSEN op4H-s-30-165/1, PSEN op4H-s-30-180/1

Item specifics

- Series

- PSENopt Series

- Resolution:

- 30 mm

- Scanning range:

- 0.2 - 19 m

- Protective field height:

- 150 - 1800 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 9 - 28 ms

- Connection type:

- M12

- Security level:

- PLe4

Review

Description

For Pilz PSENopt Series 30 mm Resolution 19 m Sensing Distance 150 mm to 1800 mm Protective Height Basic Type 4 Light Curtain with Hand Protection Replacement Parameter

Brand | From network | DADISICK |

|

|

Models

|

PSEN op4H-s-30-015/1 | QT04-40-120 2BE |

|

PSEN op4H-s-30-030/1 |

QT08-40-280 2BE | ||

PSEN op4H-s-30-045/1 | QT12-40-440 2BE |

||

PSEN op4H-s-30-060/1 | QT16-40-600 2BE | ||

PSEN op4H-s-30-075/1 | QT20-40-760 2BE | ||

PSEN op4H-s-30-090/1 | QT24-40-920 2BE | ||

PSEN op4H-s-30-105/1 | QT28-40-1080 2BE | ||

PSEN op4H-s-30-120/1 | QT30-40-1160 2BE | ||

PSEN op4H-s-30-135/1 | QT34-40-1320 2BE | ||

PSEN op4H-s-30-150/1 | QT38-40-1480 2BE | ||

PSEN op4H-s-30-165/1 | QT42-40-1640 2BE | ||

PSEN op4H-s-30-180/1 | QT46-40-1800 2BE | ||

Beam spacing | 30 mm | 40 mm | |

Protected altitude | 150 mm, 300 mm, 450 mm, 600 mm, 750 mm, 900 mm, 1050 mm, 1200 mm, 1350 mm, 1500 mm, 1650 mm, 1800 mm | 120 mm, 280 mm, 440 mm, 600 mm, 760 mm, 920 mm, 1080 mm, 1160 mm, 1320 mm, 1480 mm, 1640 mm, 1800 mm | |

Scanning range | 0.2 - 19 m | 0.3 - 20 m | |

Response time | 9 ms - 28 ms | ≤15 ms | |

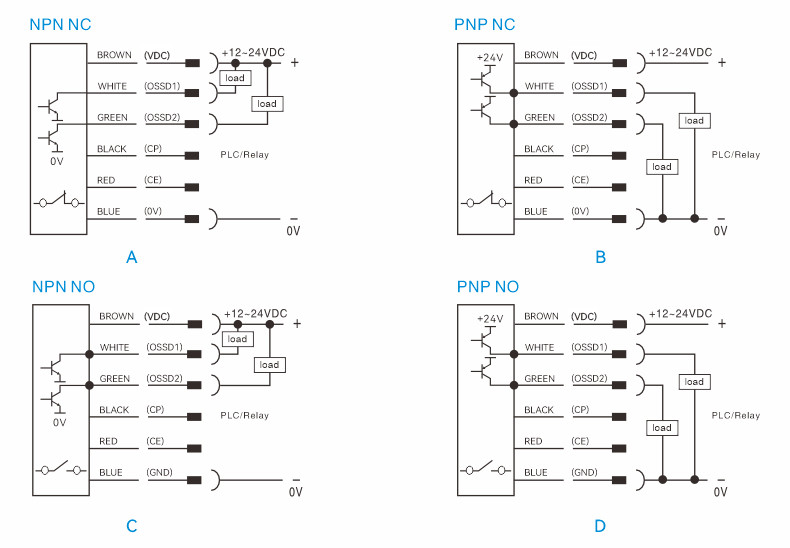

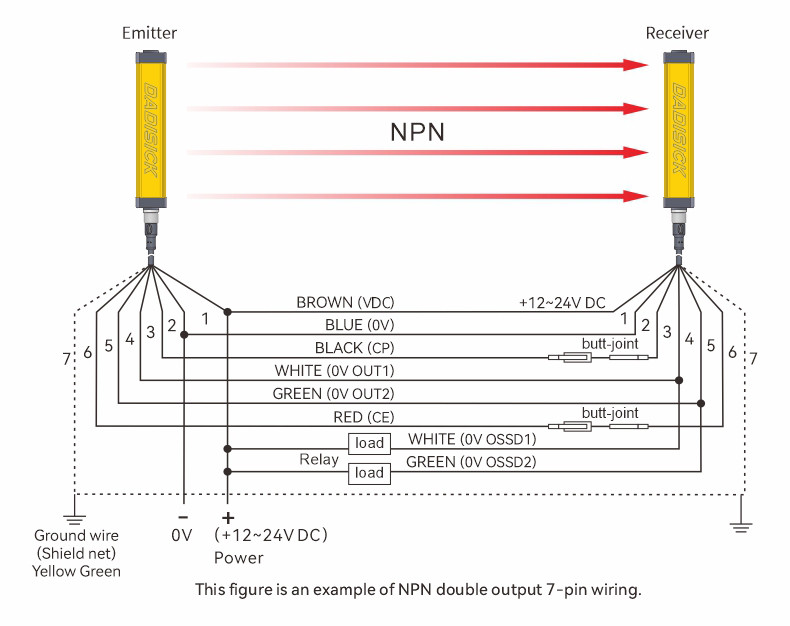

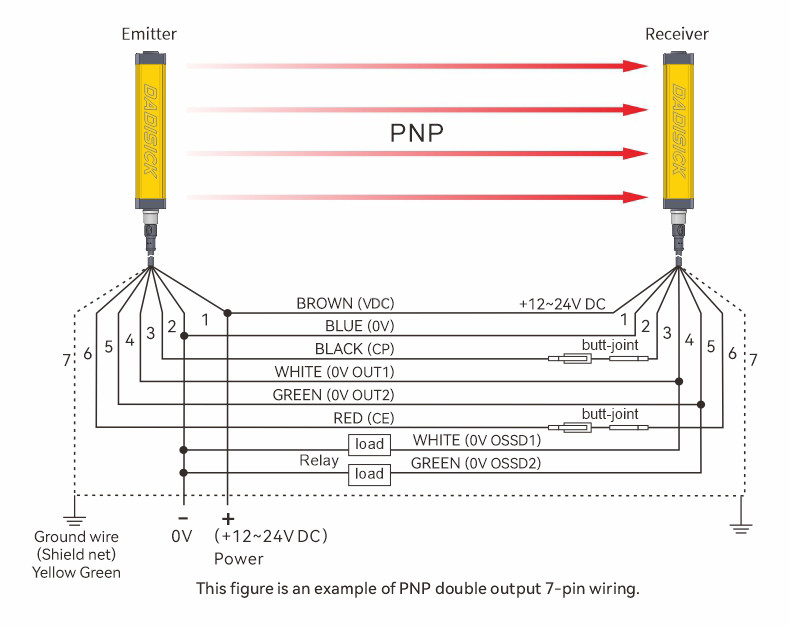

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

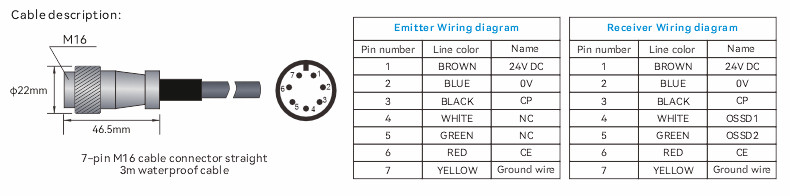

Connector | M12 | M16 | |

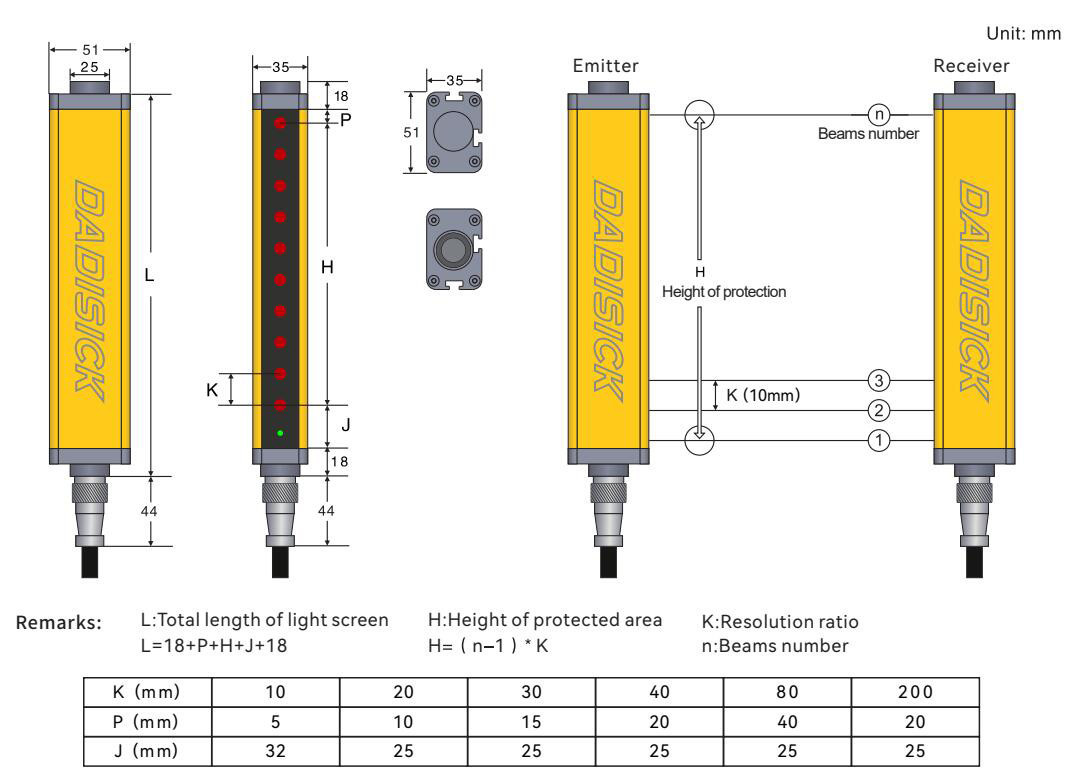

Housing cross-section | 36.9 mm x 32.3 mm | 51 mm x 35 mm | |

Safety Certificate | CE, cULus, TÜV, EAC | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand Pilz's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QT04-40-120 2BE, QT08-40-280 2BE, QT12-40-440 2BE

QT16-40-600 2BE, QT20-40-760 2BE, QT24-40-920 2BE

QT28-40-1080 2BE, QT30-40-1160 2BE, QT34-40-1320 2BE

QT38-40-1480 2BE, QT42-40-1640 2BE, QT46-40-1800 2BE

FAQ

Q:What is the significance of installing area protection safety grids?

A:

A zone safety light curtain is a type of safety device that uses invisible beams, such as infrared or laser beams, to monitor whether there are people or objects entering a hazardous area. Its purpose is to protect personnel and equipment. Without such safety measures in place, people and equipment in hazardous areas may be at risk of serious injury or even death. Installing zone safety light curtains can effectively prevent such incidents from occurring. Therefore, it is crucial to install zone safety light curtains in hazardous areas.

In addition, area protection safety grids can also help businesses comply with relevant safety regulations and standards, such as the Occupational Safety and Health Administration (OSHA) standards in the United States. These regulations and standards require companies to take necessary measures to ensure the safety of employees and the public, and to prevent accidents from occurring. Therefore, installing area protection safety grids in hazardous areas is also a demonstration of a company fulfilling its social responsibility.

In summary, the DADISCHER QSA series of area protection safety grids not only effectively protect the safety of personnel and equipment but also help businesses comply with relevant regulations and standards, fulfilling their social responsibility.

Area protection safety grids can be classified into single-sided, double-sided, and three-sided, primarily based on the direction of beam transmission.

Single-sided grids are typically suitable for scenarios where only one side needs protection, such as robot operation areas, conveyor belts, and automated assembly lines.

Double-sided grids are applicable to scenarios where both sides need protection, such as bidirectional conveyor belts and bidirectional assembly lines.

Three-sided grids are used in scenarios where three sides need protection, such as rotating equipment, material elevators, and three-dimensional shelves.

In practical applications, it is important to choose the appropriate type of area protection safety grid based on the specific requirements and characteristics of the scene, ensuring the safety and reliability of the system.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.