For Banner EZ-SCREEN LS-S Series 23mm Resolution 12m Sensing Distance SLLCP23 and SLLP23 Safety Sensors for Machines Replacement

- Model

- EZ-SCREEN LS-S Series | SLLCE23-1190-S/SLLCR23-1190-S/SLLCP23-1190, SLLCE23-1260-S/SLLCR23-1260-S/SLLCP23-1260, SLLCE23-910-S/SLLCE23-910-S/SLLCP23-910, SLLCE23-420-S/SLLCR23-420-S/SLLCP23-420, SLLCE23-630-S/SLLCR23-630-S/SLLCP23-630, SLLCE23-350-S/SLLCR23-350-S/SLLCP23-350, SLLE23-770-S/SLLR23-770-S/SLLP23-770, SLLCE23-840-S/SLLCR23-840-S/SLLCP23-840, SLLE23-630-S/SLLR23-630-S/SLLP23-630, SLLCE23-1050-S/SLLCR23-1050-S/SLLCP23-1050, SLLE23-910-S/SLLR23-910-S/SLLP23-910, SLLE23-1400-S/SLLR23-1400-S/SLLP23-1400, SLLCE23-490-S/SLLCR23-490-S/SLLCP23-490, SLLE23-1050-S/SLLR23-1050-S/SLLP23-1050, SLLCE23-770-S/SLLCR23-770-S/SLLCP23-770, SLLCE23-980-S/SLLCR23-980-S/SLLCP23-980, SLLCE23-1120-S/SLLCR23-1120-S/SLLCP23-1120, SLLE23-280-S/SLLR23-280-S/SLLP23-280, SLLE23-490-S/SLLR23-490-S/SLLP23-490, SLLE23-1260-S/SLLR23-1260-S/SLLP23-1260, SLLCE23-1330-S/SLLCR23-1330-S/SLLCP23-1330, SLLCE23-1400-S/SLLCR23-1400-S/SLLCP23-1400, SLLCE23-700-S/SLLCR23-700-S/SLLCP23-700, SLLE23-1190-S/SLLR23-1190-S/SLLP23-1190, SLLE23-350-S/SLLR23-350-S/SLLP23-350, SLLE23-420-S/SLLR23-420-S/SLLP23-420, SLLE23-980-S/SLLR23-980-S/SLLP23-980, SLLE23-1120-S/SLLR23-1120-S/SLLP23-1120, SLLE23-1330-S/SLLR23-1330-S/SLLP23-1330, SLLCE23-560-S/SLLCR23-560-S/SLLCP23-560, SLLE23-700-S/SLLR23-700-S/SLLP23-700, SLLE23-560-S/SLLR23-560-S/SLLP23-560, SLLE23-840-S/SLLR23-840-S/SLLP23-840

Item specifics

- Series:

- LS-S Series

- Resolution:

- 23mm

- Scanning range:

- 0.1-12m

- Protective field height:

- 280-1400mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 8.2-21.8ms

- Connection type:

- M12

- Security level:

- UL, CE, PLe4

Review

Description

For Banner EZ-SCREEN LS-S Series 23mm Resolution 12m Sensing Distance SLLCP23 and SLLP23 Safety Sensors for Machines Replacement Parameter

Brand | From network | DADISICK |

|||

Models | Emitter | Receiver | Pair | ||

SLLE23-280-S | SLLR23-280-S | SLLP23-280 | |||

SLLCE23-350-S | SLLCR23-350-S | SLLCP23-350 | |||

SLLE23-350-S | SLLR23-350-S | SLLP23-350 | |||

SLLCE23-420-S | SLLCR23-420-S | SLLCP23-420 | |||

SLLE23-420-S | SLLR23-420-S | SLLP23-420 | |||

SLLCE23-490-S | SLLCR23-490-S | SLLCP23-490 | |||

SLLE23-490-S | SLLR23-490-S | SLLP23-490 | |||

SLLCE23-560-S | SLLCR23-560-S | SLLCP23-560 | |||

SLLE23-560-S | SLLR23-560-S | SLLP23-560 | |||

SLLCE23-630-S | SLLCR23-630-S | SLLCP23-630 | |||

SLLE23-630-S | SLLR23-630-S | SLLP23-630 | |||

SLLCE23-700-S | SLLCR23-700-S | SLLCP23-700 | |||

SLLE23-700-S | SLLR23-700-S | SLLP23-700 | |||

SLLE23-770-S | SLLR23-770-S | SLLP23-770 | |||

SLLCE23-770-S | SLLCR23-770-S | SLLCP23-770 | |||

SLLCE23-840-S | SLLCR23-840-S | SLLCP23-840 | |||

SLLE23-840-S | SLLR23-840-S | SLLP23-840 | |||

SLLCE23-910-S | SLLCE23-910-S | SLLCP23-910 | |||

SLLE23-910-S | SLLR23-910-S | SLLP23-910 | |||

SLLCE23-980-S | SLLCR23-980-S | SLLCP23-980 | |||

SLLE23-980-S | SLLR23-980-S | SLLP23-980 | |||

SLLCE23-1050-S | SLLCR23-1050-S | SLLCP23-1050 | |||

SLLE23-1050-S | SLLR23-1050-S | SLLP23-1050 | |||

SLLCE23-1120-S | SLLCR23-1120-S | SLLCP23-1120 | |||

SLLE23-1120-S | SLLR23-1120-S | SLLP23-1120 | |||

SLLCE23-1190-S | SLLCR23-1190-S | SLLCP23-1190 | |||

SLLE23-1190-S | SLLR23-1190-S | SLLP23-1190 | |||

SLLCE23-1260-S | SLLCR23-1260-S | SLLCP23-1260 | |||

SLLE23-1260-S | SLLR23-1260-S | SLLP23-1260 | |||

SLLCE23-1330-S | SLLCR23-1330-S | SLLCP23-1330 | |||

SLLE23-1330-S | SLLR23-1330-S | SLLP23-1330 | |||

SLLE23-1400-S | SLLR23-1400-S | SLLP23-1400 | |||

SLLCE23-1400-S | SLLCR23-1400-S | SLLCP23-1400 | |||

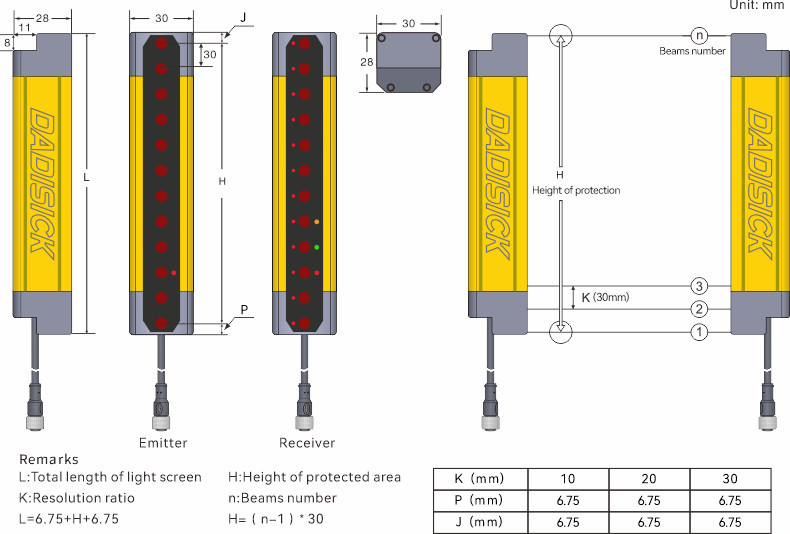

Beam spacing | 23mm | 20mm | |||

Protected altitude | 280mm/350mm/420mm/490mm/560mm/630mm/700mm/770mm/840mm/910mm/980mm/1050mm/1120mm/1190mm/1260mm/1330mm/1400mm | 260mm/340mm/420mm/500mm/540mm/620mm/700mm/780mm/820mm/900mm/980mm/1060mm/1100mm/1180mm/1260mm/1340mm/1380mm | |||

Scanning range | 0.1-12m | 0.3-15m | |||

Response time | 8.2-21.8ms | ≤15ms | |||

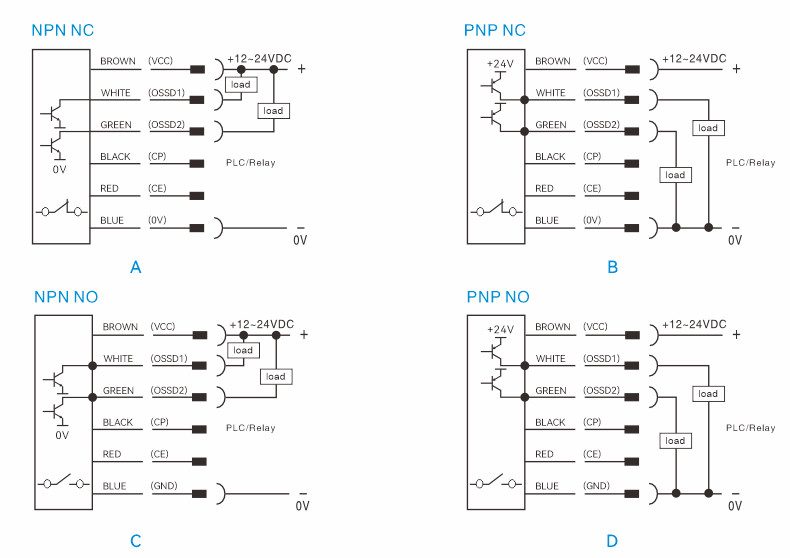

Output method | 2 PNP | 2 PNP | |||

Reliability and durability | IP65/IP67 | IP65 | |||

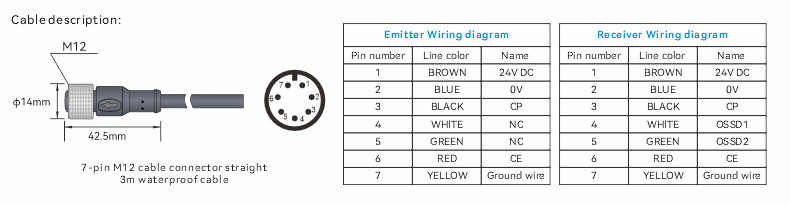

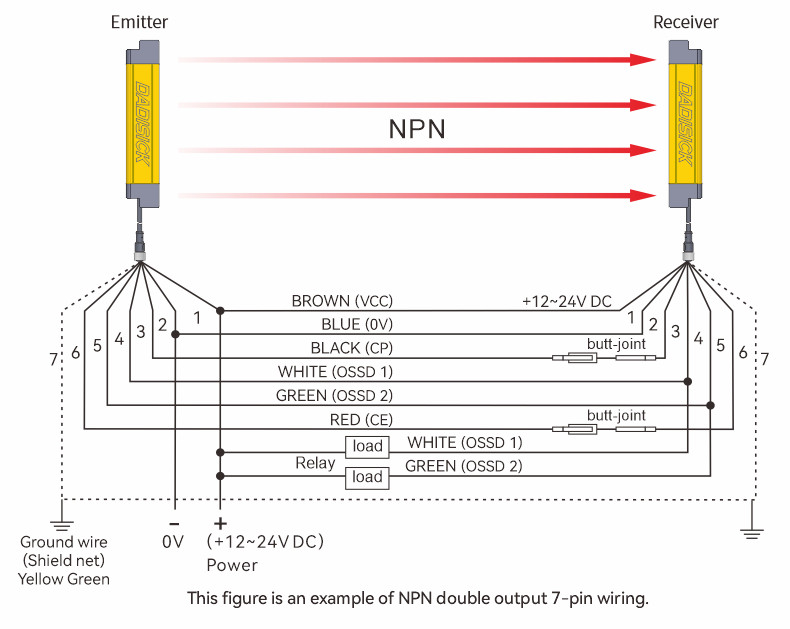

Connector | M12 | M12 | |||

Housing cross-section | 36 x 45mm | 28 x 30mm | |||

Safety Certificate | UL, CE, PLe4 | TÜV, UL, CE, RoHS, GB | |||

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand Banner's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QO14/20-260 2BD, QO18/20-340 2BD, QO22/20-420 2BD, QO26/20-500 2BD, QO28/20-540 2BD, QO32/20-620 2BD, QO36/20-700 2BD, QO40/20-780 2BD, QO42/20-820 2BD, QO46/20-900 2BD, QO50/20-980 2BD, QO54/20-1060 2BD, QO56/20-1100 2BD, QO60/20-1180 2BD, QO64/20-1260 2BD, QO68/20-1340 2BD, QO70/20-1380 2BD

FAQ

Safety Light Curtains - Making Punching Operations Safer

I believe many friends are aware of the significant safety risks involved in operating a punch press. When carrying out punching operations, the operators need to have a strong awareness of safety and be familiar with the proper operation of the machine. However, despite these precautions, accidents related to hand injuries still occur in the stamping industry every year, highlighting the importance of safety in industrial production. Installing safety light curtains on punch press equipment has become an effective safety protection solution employed by various machinery manufacturers to prevent mechanical accidents and maintain a safe working environment.

Configuring a punch-specific safety light curtain protection device with a controller not only provides safety protection but also does not interfere with the material feeding and loading operations during punch press work. This is currently considered a reliable professional-level solution for punch press safety protection.

The principle of the safety light curtain is based on the use of an infrared light grid to form a protective screen. It transmits corresponding signals through the interruption or blocking of the light beams, allowing for the control of machine equipment to stop or run, thereby creating intelligent protection. During the operation of a punch press, operators can safely carry out material feeding and loading operations. If someone accidentally reaches the punching range, the light curtain will send a signal to the control device, causing the punch press to stop working, thus ensuring the safety of personnel and the machine equipment.

Due to its widespread application in the stamping industry, safety light curtains are also known as punch press protectors or hand protection grids. The installation and use of safety light curtains for punch press equipment are convenient, fast, and require minimal installation space. Safety light curtains offer precise light detection, stable performance, and reliable safety. Their durable characteristics ensure a long lifespan, making them an economical and efficient professional safety protection device for industries such as stamping and industrial production.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.