For Banner EZ-SCREEN LP Series 14mm Resolution 1110mm to 1250mm Protective Height SLPCP14 and SLPMP14 and SLPP14 Safety Sensors for Machines Replacement

- Model

- EZ-SCREEN LP Series | SLPCP14-1110, SLPCP14-1110P88, SLPCP14-1250P88, SLPCP141250N, SLPMP14-1110, SLPMP14-1250, SLPP14-1110, SLPP14-1110P88, SLPP14-1250, SLPP14-1250P88

Item specifics

- Series

- LP Series

- Resolution:

- 14mm

- Scanning range:

- 0.1-7 m

- Protective field height:

- 1110-1250mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 28.5-31.5ms

- Connection type:

- M12

- Security level:

- UL, CE, PLe4

Review

Description

For Banner EZ-SCREEN LP Series 14mm Resolution 1110mm-1250mm Protective Height SLPCP14 and SLPMP14 and SLPP14 Safety Sensors for Machines Replacement Parameter

Brand | From network | DADISICK |

|

Models | SLPCP14-1110 | ||

SLPCP14-1110P88 | |||

SLPMP14-1110 |

|||

SLPP14-1110 | |||

SLPP14-1110P88 | |||

SLPCP14-1250P88 | |||

SLPCP141250N | |||

SLPMP14-1250 | |||

SLPP14-1250 | |||

SLPP14-1250P88 | |||

Beam spacing | 14mm | 10mm | |

Protected altitude | 1110mm/1250mm | 1110mm/1250mm | |

Scanning range | 0.1-7 m | 0.3-10m | |

Response time | 28.5-31.5ms | ≤15ms | |

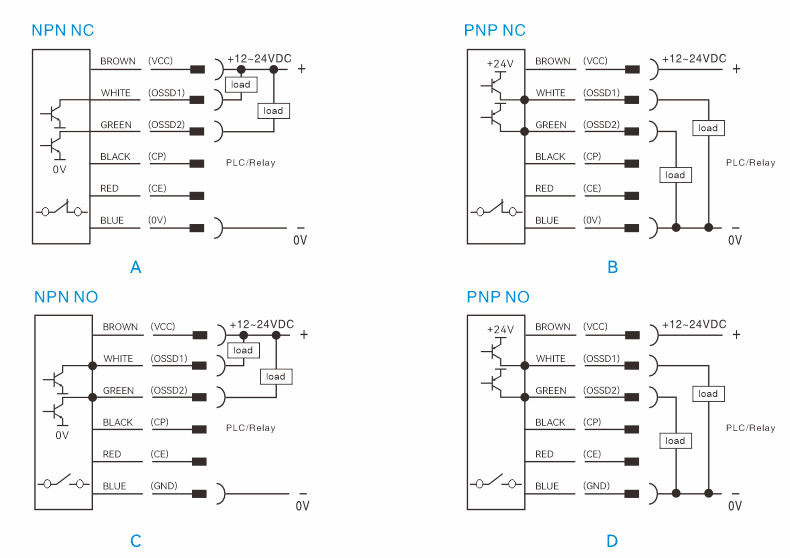

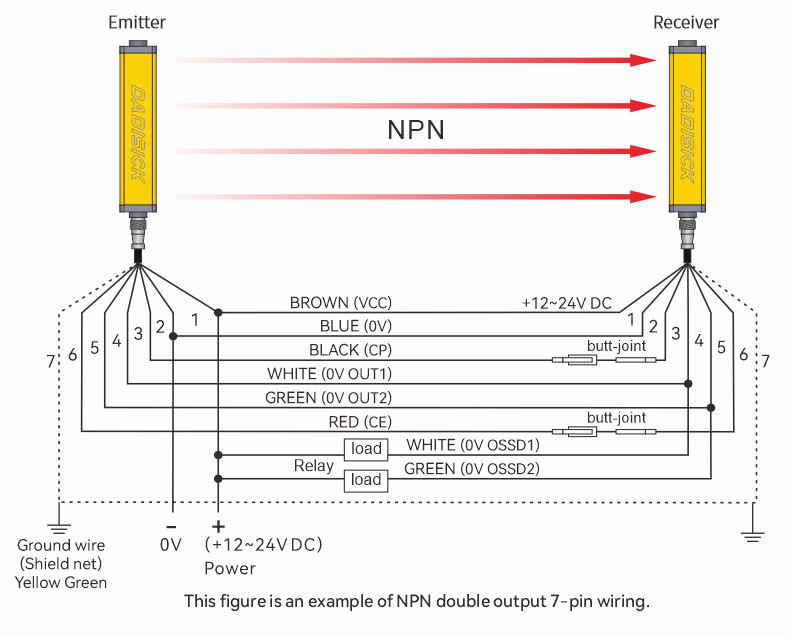

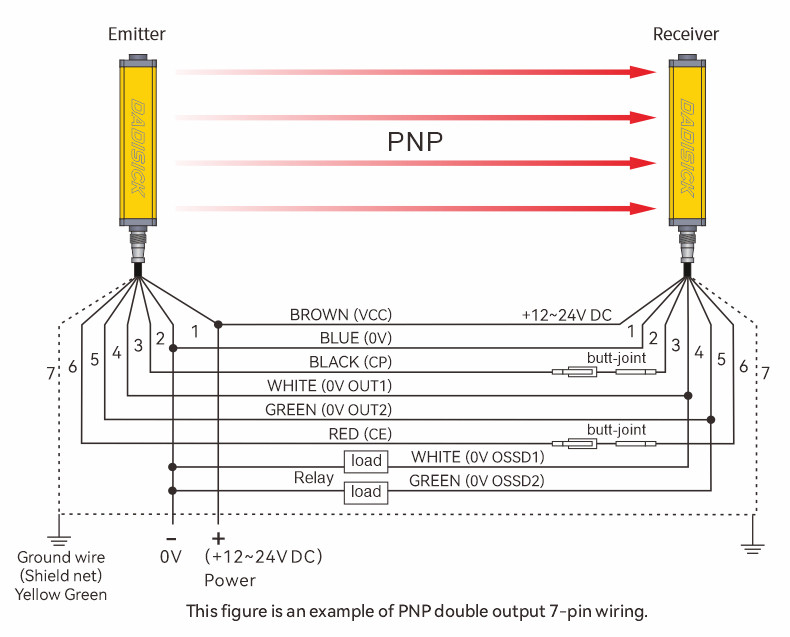

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

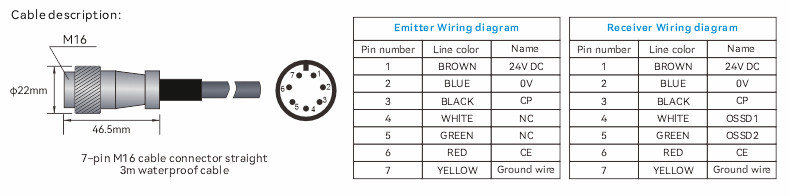

Connector | M12 | M16 | |

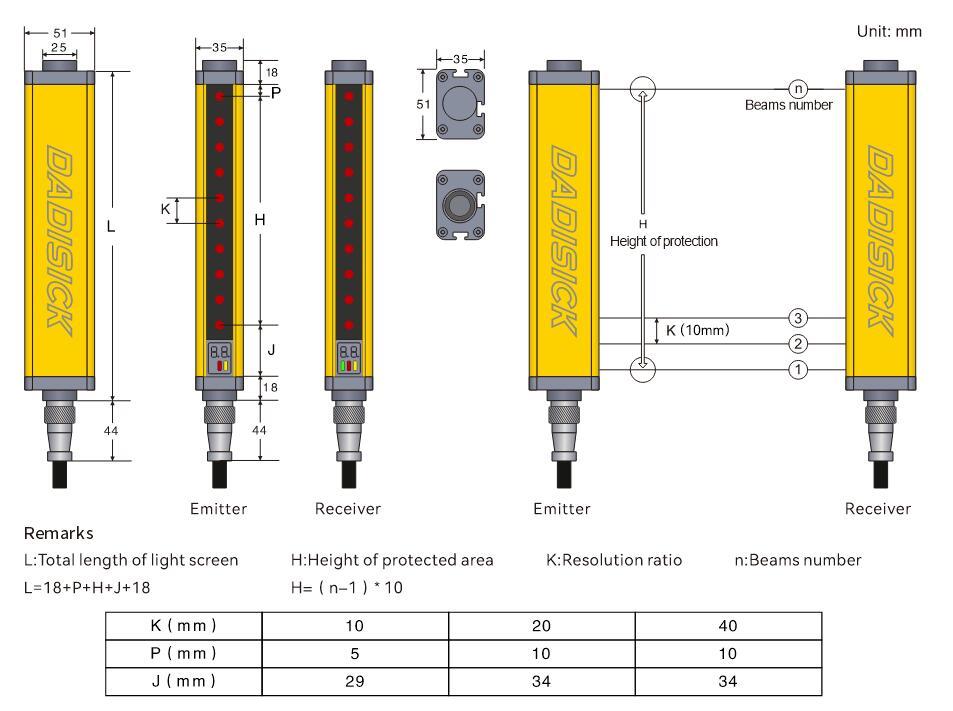

Housing cross-section | 28 x 26mm | 51 x 35mm | |

Safety Certificate | UL, CE, PLe4 | TÜV, UL, CE, RoHS, GB | |

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand Banner's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

FAQ

Interference Solution for Safety Light Curtains

DADISICK, a highly sensitive protection device, is increasingly demonstrating strong momentum in its application within safety systems in the manufacturing industry. In some high-end manufacturing plants, large workstations have fully adopted two-dimensional or even three-dimensional protection systems.

More production equipment, in situations where frequent intervention is required, almost always choose to use safety light curtains as a solution after considering risks such as material splashing, sparks, and dust dispersion. The benefits of using safety light curtains are as follows:

1. The technology industry chain for sensitive protection devices is mature, with clear product classifications, and various resolution and safety performance levels can meet requirements.

2. Safety technology is developing rapidly, with continuous breakthroughs in improvement technologies in various aspects and the formation of norms. The future path of standardization is clear.

3. As an active defense technology, safety light curtains, in most cases, allow for automatic reset, effectively addressing grounding issues in the production process, significantly reducing operational complexity, and improving production efficiency.

DADISICK offers safety light curtains and scanners as products. As a safety-sensitive protection device, safety light curtains bring convenience in usage, but signal interference is also one of the issues that must be addressed.

Signal interference in safety light curtains typically arises from two aspects:

Interference from the environment:

If there are reflective surfaces near the light beams emitted by the safety light curtains, passive reflections can cause the receiving end of the curtains to receive incorrect reflection signals, resulting in the inability to detect intrusions within the protected area.

Interference between neighboring light curtains:

Due to the widespread use of safety light curtains in adjacent areas and the long protective distance of the curtain components themselves, signal misalignment between the transmitting and receiving ends of neighboring light curtains can occur.

Interference solutions for safety light curtains.

To effectively avoid the various types of interference mentioned above, we can employ physical positioning and technical measures.

Regarding the positioning of safety light curtains in relation to reflective surfaces:

[1] Reflective surface

[2] Safety light curtain transmitter

[3] Safety light curtain receiver

[4] Half scanning angle

[5] Minimum distance from safety light curtain to the reflective surface

Physical positioning:

The safety light curtains themselves have fixed scanning angles, and specific parameters can be found in the light curtain technical manual. The positioning of the transmitter and receiver of the light curtain can also be determined based on the working conditions. With these two sets of parameters, the minimum distance to prevent reflective interference can be calculated using trigonometric functions such as tangent (tan) or cotangent (cot).

In cases where multiple sets of neighboring light curtains are used, additional physical barriers can be utilized or the installation sequence of the receiver and transmitter can be reversed to address signal interference between the light curtains.

Usage of multiple sets of neighboring light curtains:

Technical measures:

In addition to physical means, certain models of safety light curtains have integrated encoding functionality, which prevents interference even when installed close to each other physically. The encoding feature allows the light curtains to function properly even when subjected to interference from other light curtains. This is particularly useful in cases where the transmitter of one pair of light curtains may directly emit towards the receiver of another pair of light curtains. As long as these two pairs of light curtains are configured with different encodings, the issue of mutual interference between them can be effectively resolved.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.