For Banner EZ-SCREEN LS-S Series 14mm Resolution 12m Sensing Distance SLLP14 and SLLCP14 Infrared Safety Light Curtain Replacement

- Model

- EZ-SCREEN LS-S Series | SLLCE14-350-S/SLLCR14-350-SLLCP14-350, SLLCE14-350-S/SLLCR14-350-S/SLLCP14-350, SLLE14-280-S/SLLR14-280-S/SLLP14-280, SLLCE14-630-S/SLLCR14-630-S/SLLCP14-630, SLLE14-560-S/SLLR14-560-S/SLLP14-560, SLLE14-420-S.SLLR14-420-S/SLLP14-420, SLLE14-490-S/SLLR14-490-S/SLLP14-490, SLLCE14-420-S/SLLCR14-420-S/SLLCP14-420, SLLE14-630-S/SLLR14-630-S/SLLP14-630, SLLE14-700-S/SLLR14-700-S/SLLP14-700, SLLE14-350-S/SLLR14-350-S/SLLP14-350, SLLCE14-490-S/SLLCR14-490-S/SLLCP14-490, SLLCE14-560-S/SLLCR14-560-S/SLLCP14-560, SLLCE14-700-S/SLLCR14-700-S/SLLCP14-700

Item specifics

- Series:

- LS-S Series

- Resolution:

- 14mm

- Scanning range:

- 0.1-12m

- Protective field height:

- 280-700mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 11.6-21.8ms

- Connection type:

- M12

- Security level:

- UL, CE, PLe4

Review

Description

For Banner EZ-SCREEN LS-S Series 14mm Resolution 12m Sensing Distance SLLP14 and SLLCP14 Infrared Safety Light Curtain Replacement Parameter

Brand | From network | DADISICK |

|||

Models | Emitter | Receiver | Pair | ||

SLLE14-280-S | SLLR14-280-S | SLLP14-280 | |||

SLLCE14-350-S | SLLCR14-350-S | SLLCP14-350 | |||

SLLE14-350-S | SLLR14-350-S | SLLP14-350 | |||

SLLE14-420-S | SLLR14-420-S | SLLP14-420 | |||

SLLCE14-420-S | SLLCR14-420-S | SLLCP14-420 | |||

SLLE14-490-S | SLLR14-490-S | SLLP14-490 | |||

SLLCE14-490-S | SLLCR14-490-S | SLLCP14-490 | |||

SLLE14-560-S | SLLR14-560-S | SLLP14-560 | |||

SLLCE14-560-S | SLLCR14-560-S | SLLCP14-560 | |||

SLLCE14-630-S | SLLCR14-630-S | SLLCP14-630 | |||

SLLE14-630-S | SLLR14-630-S | SLLP14-630 | |||

SLLE14-700-S | SLLR14-700-S | SLLP14-700 | |||

SLLCE14-700-S | SLLCR14-700-S | SLLCP14-700 | |||

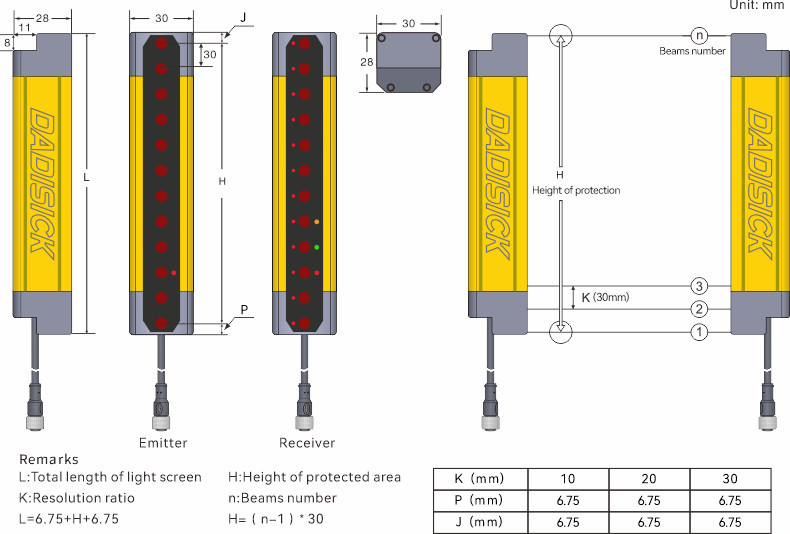

Beam spacing | 14mm | 10mm | |||

Protected altitude | 280mm/350mm/420mm/490mm/560mm/630mm/700mm | 270mm/350mm/410mm/490mm/550mm/630mm/690mm | |||

Scanning range | 0.1-12m | 0.3-15m | |||

Response time | 11.6-21.8ms | ≤15ms | |||

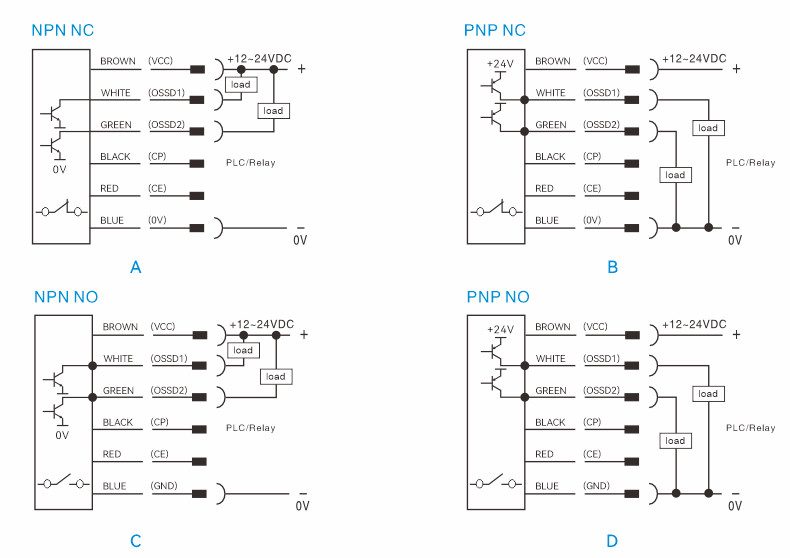

Output method | 2 PNP | 2 PNP | |||

Reliability and durability | IP65/IP67 | IP65 | |||

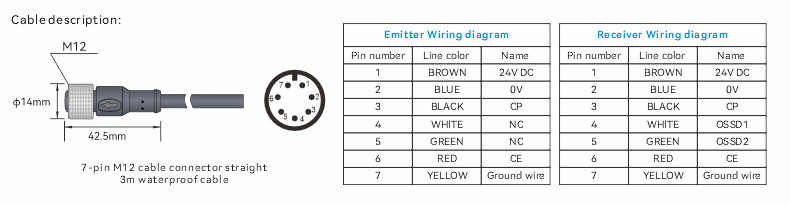

Connector | M12 | M12 | |||

Housing cross-section | 36 x 45mm | 28 x 30mm | |||

Safety Certificate | UL, CE, PLe4 | TÜV, UL, CE, RoHS, GB | |||

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand Banner's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QO28/10-270 2BD, QO36/10-350 2BD, QO42/10-410 2BD, QO50/10-490 2BD, QO56/10-550 2BD, QO64/10-630 2BD, QO70/10-690 2BD

FAQ

How Safety Light Curtain Used in Injection Molding Machine?

A safety light curtain is an advanced optoelectronic protective device that can be used as a safety guard, infrared safety guard, or press protection device. It is suitable for potentially hazardous machinery such as stamping machines, forging machines, and automated equipment, which can pose a risk of personal injury. The installation of a safety light curtain can effectively protect personal safety.

Injection molding machines and punch presses are both large-scale mechanical equipment. When installing safety light curtain protection devices, special methods can be used for protection. Based on the actual usage of injection molding machines, the selection and improvement of self-checking functions of safety light curtains can be done to determine the beam spacing, height protection, distance protection, and output mode, ensuring that when a safety light curtain malfunctions, it does not send incorrect signals to the controlled equipment.

Maintenance, repair, and upkeep of injection molding machines must be carried out by qualified and experienced experts or technicians. The operation of the injection molding machine should only be done when all safety devices are functioning properly. The safety light curtain protection device installed on the machine is designed to protect the operator's personal safety and ensure that the product and equipment are not damaged. Therefore, it is not allowed to dismantle safety light curtains or other protective devices without proper authorization, and the software programs in the devices should not be modified randomly. Before using the machine, it is necessary to check whether the safety protection devices are functioning correctly.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.