EOS2 Series 50 mm Resolution 12 m Sensing Distance 160 mm to 2260 mm Protective Height XS Safety Light Curtain Replacement

- Model

- EOS2 Series | EOS2 155 XS, EOS2 305 XS, EOS2 455 XS, EOS2 605 XS, EOS2 755 XS, EOS2 905 XS, EOS2 1055 XS, EOS2 1205 XS, EOS2 1355 XS, EOS2 1505 XS, EOS2 1655 XS, EOS2 1805 XS, EOS2 1955 XS, EOS2 2105 XS, EOS2 2255 XS

Item specifics

- Series:

- EOS2 Series

- Resolution:

- 50 mm

- Scanning range:

- 12 m

- Protective field height:

- 160 - 2260 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 3.5 - 16 ms

- Connection type:

- M12

- security level:

- PLc2

Review

Description

EOS2 Series 50 mm Resolution 12 m Sensing Distance 160 mm to 2260 mm Protective Height XS Safety Light Curtain Replacement Parameter

Brand | From network | DADISICK |

|

|

Models

|

EOS2 155 XS | QT06-40-200 2BD |

|

EOS2 305 XS |

QT08-40-280 2BD | ||

EOS2 455 XS | QT12-40-440 2BD |

||

EOS2 605 XS | QT16-40-600 2BD | ||

EOS2 755 XS | QT20-40-760 2BD | ||

EOS2 905 XS | QT24-40-920 2BD | ||

EOS2 1055 XS | QT28-40-1080 2BD | ||

EOS2 1205 XS | QT32-40-1240 2BD | ||

EOS2 1355 XS | QT36-40-1400 2BD | ||

EOS2 1505 XS | QT38-40-1480 2BD | ||

EOS2 1655 XS | QT42-40-1640 2BD | ||

EOS2 1805 XS | QT46-40-1800 2BD | ||

EOS2 1955 XS | QT50-40-1960 2BD | ||

EOS2 2105 XS | QT54-40-2120 2BD | ||

EOS2 2255 XS | QT58-40-2280 2BD | ||

Beam spacing | 50 mm | 40 mm | |

Protected altitude | 160 mm, 310 mm, 460 mm, 610 mm, 760 mm, 910 mm, 1060 mm, 1210 mm, 1360 mm, 1510 mm, 1660 mm, 1810 mm, 1960 mm, 2110 mm, 2260 mm | 200 mm, 280 mm, 440 mm, 600 mm, 760 mm, 920 mm, 1080 mm, 1240 mm, 1400 mm, 1480 mm, 1640 mm, 1800 mm, 1960 mm, 2120 mm, 2280 mm | |

Scanning range | 12 m | 0.3 - 15 m | |

Response time | 3.5 ms - 16 ms | ≤15 ms | |

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65, IP67 | IP65 | |

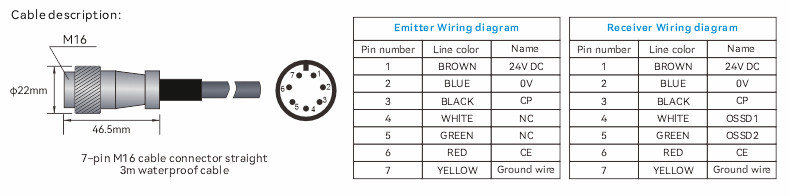

Connector | M12 | M16 | |

Housing cross-section | 28 mm x 30 mm | 51 mm x 35 mm | |

Safety Certificate | CE, TÜV, UL, TS, RoHS, UKCA, PLc2 | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

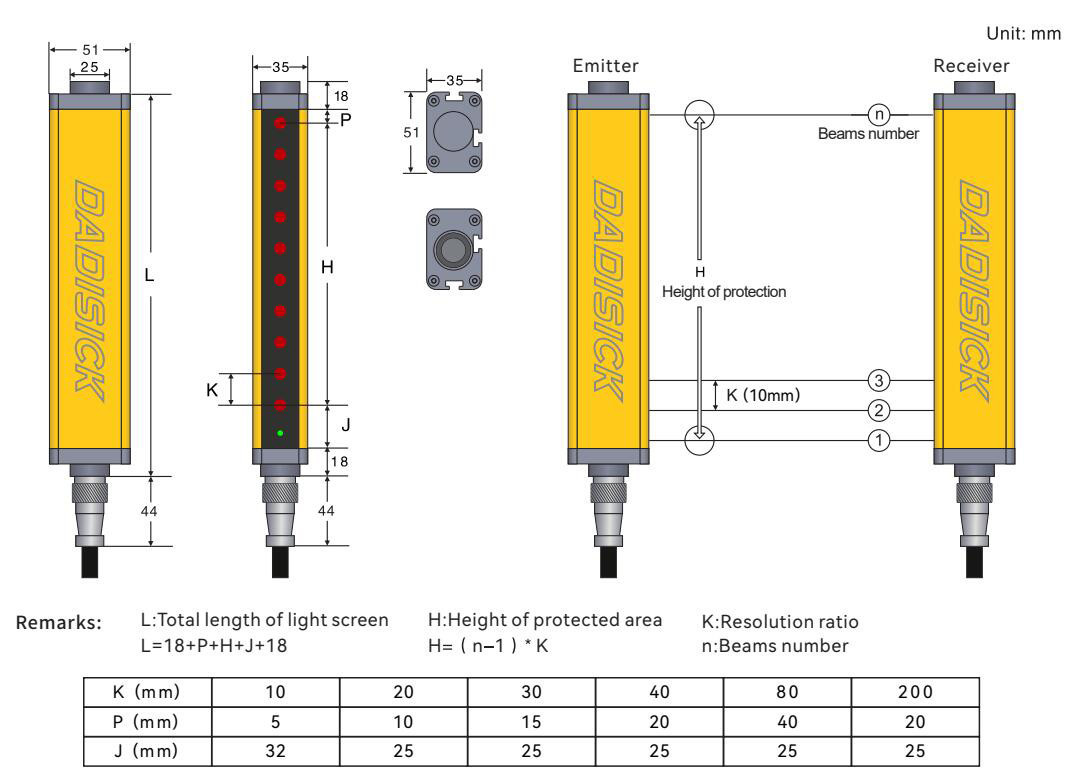

Product model display instructions

The product models displayed on this page are only used to describe and compare the characteristics, specifications, and performance of different products. These models do not represent recommendations or associations for any specific brand or company. When users choose products, please understand and compare the detailed information of each brand's products on your own.

Product recommendations

Model:

QT06-40-200 2BD, QT08-40-280 2BD, QT12-40-440 2BD

QT16-40-600 2BD, QT20-40-760 2BD, QT24-40-920 2BD

QT28-40-1080 2BD, QT32-40-1240 2BD, QT36-40-1400 2BD

QT38-40-1480 2BD, QT42-40-1640 2BD, QT46-40-1800 2BD

QT50-40-1960 2BD, QT54-40-2120 2BD, QT58-40-2280 2BD

FAQ

Q: How much do you know about the through-beam light curtain used in industrial production?

A:

The through-beam light curtain, also known as an infrared light curtain, light curtain, or photoelectric protection device, is widely used in industrial production.

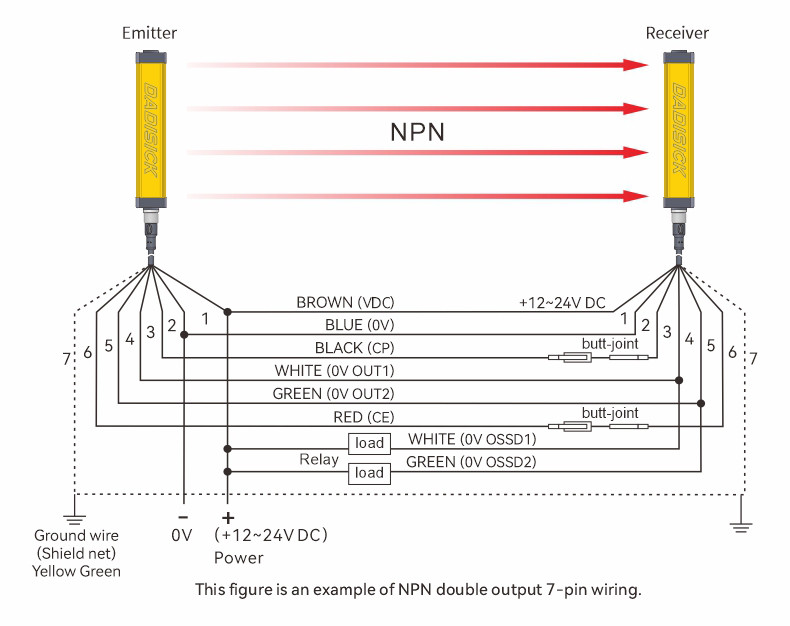

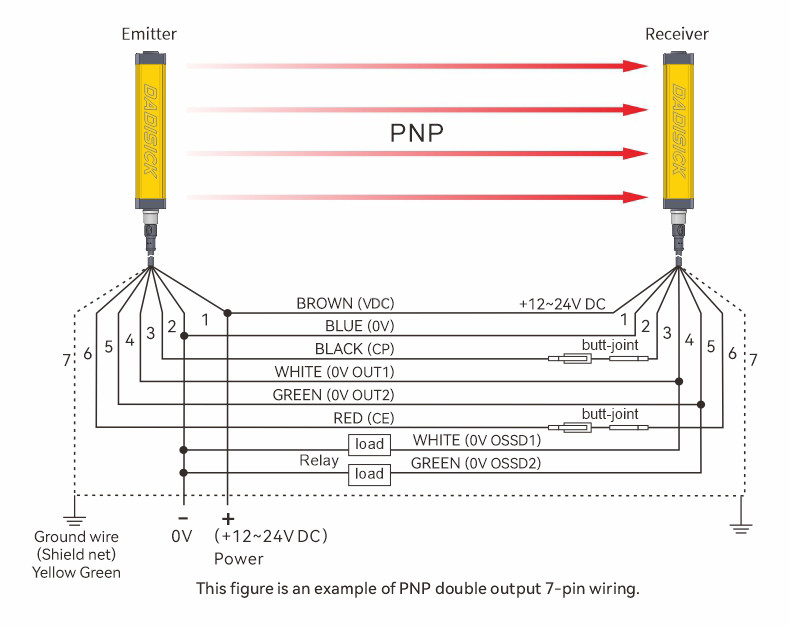

The working principle of a through-beam light curtain is as follows: The emitter emits light, which is received by the receiver, forming a beam of light. The internal circuit processes the ON/OFF status of the beam to trigger actions as stopping the equipment or issuing a safety alert.

Through-beam light curtains find applications in various fields including punch presses, shearing equipment, metal cutting devices, industrial robots, injection molding machines, filter presses, automated welding lines, and automated assembly lines.

Characteristics of the photoelectric grating: It has a compact design, making it convenient for transportation and installation. It offers various installation methods, providing flexibility and convenience. The photoelectric grating has a self-checking function, ensuring higher safety. It also has the ability to resist water, light interference, and magnetic interference.

Some general parameters include a protection height ranging from 30-2000mm, beam pitch options of 10mm, 20mm, 40mm, etc., protection distance ranging from 0-2000mm, response time less than 10mm, and a through-beam configuration. The casing is rated IP65 for protection.

In industrial production, the use of photoelectric gratings can effectively prevent safety accidents, eliminate risks for operators and third parties, reduce accident costs, improve company productivity, protect employee safety, and promote stable company development.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.