For ReeR Vision Series 30 mm Resolution 16 m Sensing Distance 160 mm to 1810 mm Protective Height VH Safety Light Curtain Replacement

- Model

- Vision Series | V 153 H, V 303 H, V 453 H, V 603 H, V 753 H, V 903 H, V 1053 H, V 1203 H, V 1353 H, V 1503 H, V 1653 H, V 1803 H

Item specifics

- Series:

- Vision Series

- Resolution:

- 30 mm

- Scanning range:

- 16 m

- Protective field height:

- 160 - 1810 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 6 - 17 ms

- Connection type:

- M12

- security level:

- PLc2

Review

Description

For ReeR Vision Series 30 mm Resolution 16 m Sensing Distance 160 mm to 1810 mm Protective Height VH Safety Light Curtain Replacement Parameter

Brand | From network | DADISICK |

|

|

Models

|

V 153 H | QT06-30-150 2BE |

|

V 303 H |

QT12-30-330 2BE | ||

V 453 H | QT16-30-450 2BE |

||

V 603 H | QT22-30-630 2BE | ||

V 753 H | QT26-30-750 2BE | ||

V 903 H | QT32-30-930 2BE | ||

V 1053 H | QT28-40-1080 2BE | ||

V 1203 H | QT32-40-1240 2BE | ||

V 1353 H | QT34-40-1320 2BE | ||

V 1503 H | QT38-40-1480 2BE | ||

V 1653 H | QT42-40-1640 2BE | ||

V 1803 H | QT46-40-1800 2BE | ||

Beam spacing | 30 mm | 30 mm, 40 mm | |

Protected altitude | 160 mm, 310 mm, 460 mm, 610 mm, 760 mm, 910 mm, 1060 mm, 1210 mm, 1360 mm, 1510 mm, 1660 mm, 1810 mm | 150 mm, 330 mm, 450 mm, 630 mm, 750 mm, 930 mm, 1080 mm, 1240 mm, 1320 mm, 1480 mm, 1640 mm, 1800 mm | |

Scanning range | 16 m | 0.3 - 20 m | |

Response time | 6 ms - 17 ms | ≤15 ms | |

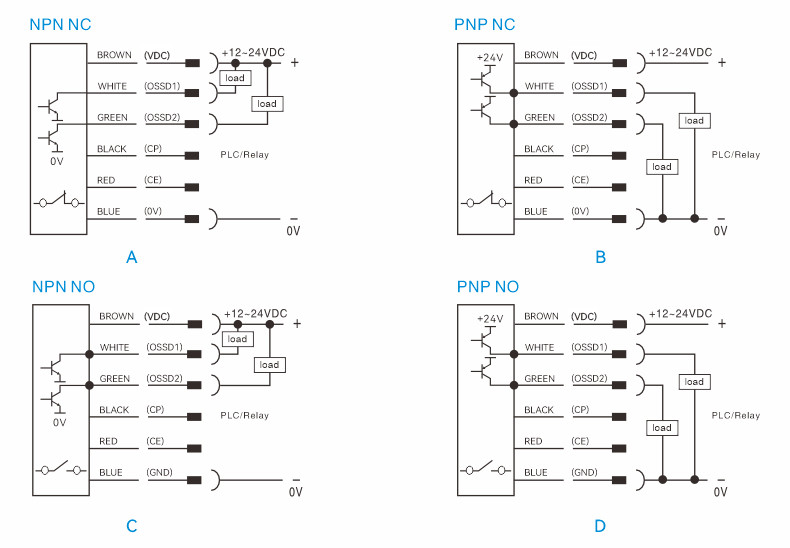

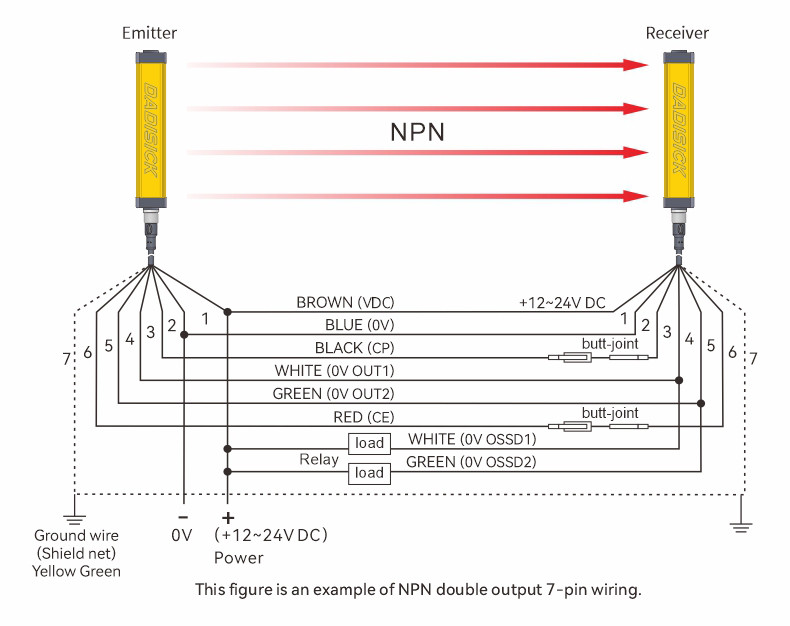

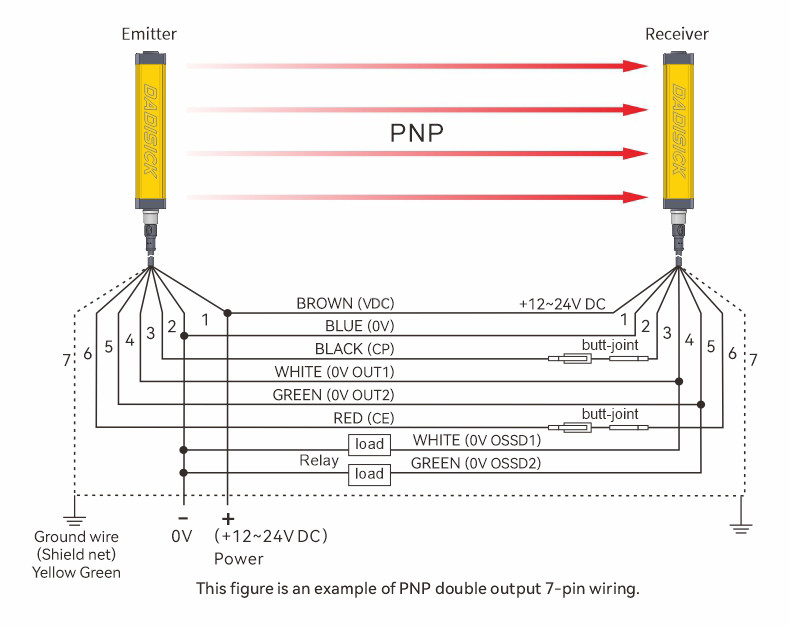

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

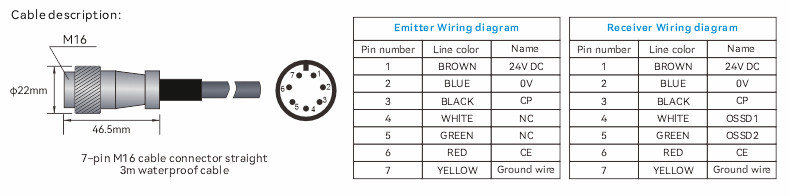

Connector | M12 | M16 | |

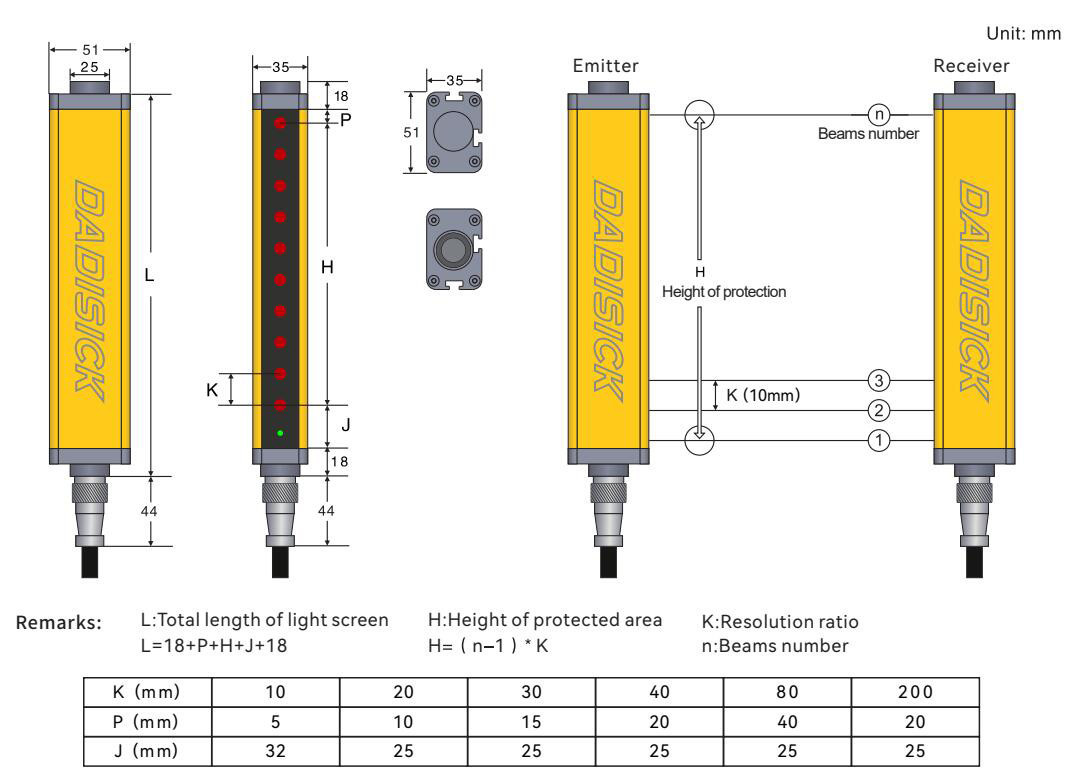

Housing cross-section | 45 mm x 35 mm | 51 mm x 35 mm | |

Safety Certificate | CE, TÜV, cULus,RoHS,UKCA | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand ReeR's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QT06-30-150 2BE, QT12-30-330 2BE, QT16-30-450 2BE

QT22-30-630 2BE, QT26-30-750 2BE, QT32-30-930 2BE

QT28-40-1080 2BE, QT32-40-1240 2BE, QT34-40-1320 2BE

QT38-40-1480 2BE, QT42-40-1640 2BE, QT46-40-1800 2BE

FAQ

Q: Electric Punch Press Safety Light Curtain and Old-fashioned Hydraulic Press Safety Light Curtain

A:

Punch presses are widely used in the manufacturing industry. During operation, punch presses require power to be applied to the worktable where the workpiece is placed. Operators need to position and adjust the workpiece. Without protective devices on the punch press, operators are at risk of injury from the high-speed descending punch.

To ensure the safe operation and production of the equipment and protect the personal safety of operators, punch presses need to be equipped with safety protection devices. However, conventional safety devices such as limit switches rely on human observation to control their activation, which often fails to achieve the desired level of protection.

Safety Light Curtain

To effectively and quickly eliminate the high-speed inertia of punch presses, installing an infrared optoelectronic protective device (also known as a safety light curtain or safety light screen) is an ideal choice.

The optical emitter and receiver of the optoelectronic protective device detect and output detection result information through a controller. When other objects or the operator's body enters the working area of the punch press, the light curtain formed between the emitter and receiver detects the anomaly. The on/off signal of the light curtain is processed by internal circuitry and transmitted to the PLC or alarm circuit through a transmission line, enabling equipment shutdown or triggering a safety alarm. It effectively prevents safety accidents.

Currently, DADISCHACK excels in performance and stability in the market of infrared optoelectronic protective devices. It has a high level of recognition in the industry and is relatively trustworthy and recommended. The selection and purchase of infrared optoelectronic protective devices for punch presses are crucial for industrial production safety and personal safety and should be approached with caution.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.