For ReeR Safegate Series Safety Light Curtain with Status Lamp Replacement 500/400/300 mm Resolution | 40 m and 80 m Max Operating Range | 510 mm to 910 mm Protective Height

- Model

- Safegate Series | SAFEGATE SO 2B LR, SAFEGATE SO 2B LR-A, SAFEGATE SO 3B LR, SAFEGATE SO 3B LR-A, SAFEGATE SO 4B LR, SAFEGATE SO 4B LR-A

Item specifics

- Series:

- Safegate Series

- Resolution:

- 500 mm / 400 mm / 300 mm

- Scanning range:

- 6...40 m / 8...80 m

- Protective field height:

- 510 mm - 910 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 5.5 ms

- Connection type:

- M12

- Security level:

- PLe4

Review

Description

For ReeR Safegate Series Safety Light Curtain Replacement Parameter

Brand | From network | DADISICK |

|

|

Models

|

SAFEGATE SO 2B LR | QT04-200-600-2BH |

|

SAFEGATE SO 2B LR-A |

|||

SAFEGATE SO 3B LR | QT06-200-1000-2BH |

||

SAFEGATE SO 3B LR-A | |||

SAFEGATE SO 4B LR | |||

SAFEGATE SO 4B LR-A | |||

Beam spacing | 500 mm / 400 mm / 300 mm | 200 mm | |

Protected altitude | 510 mm, 510 mm, 810 mm 810 mm, 910 mm, 910 mm | 600 mm, 1000 mm | |

Scanning range | Short distance: 6...40 m Long diatance: 8...80 m | 0.3 m - 40 m | |

Response time | 5.5 ms | ≤15 ms | |

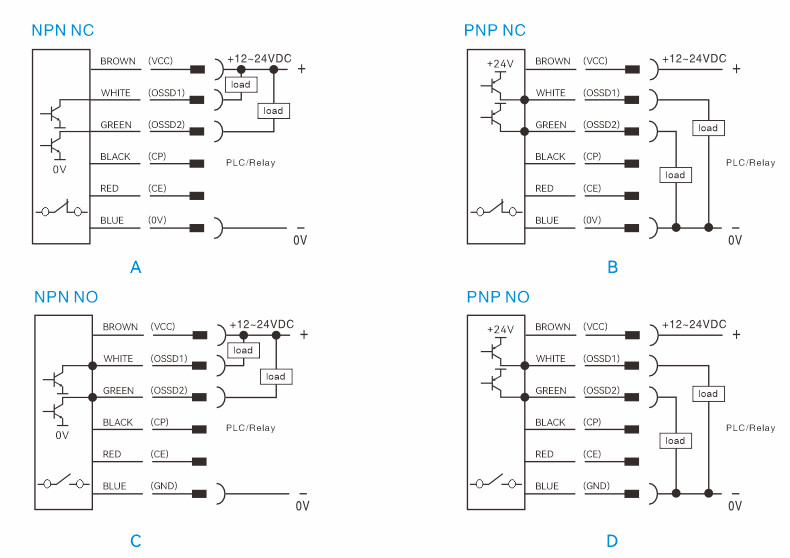

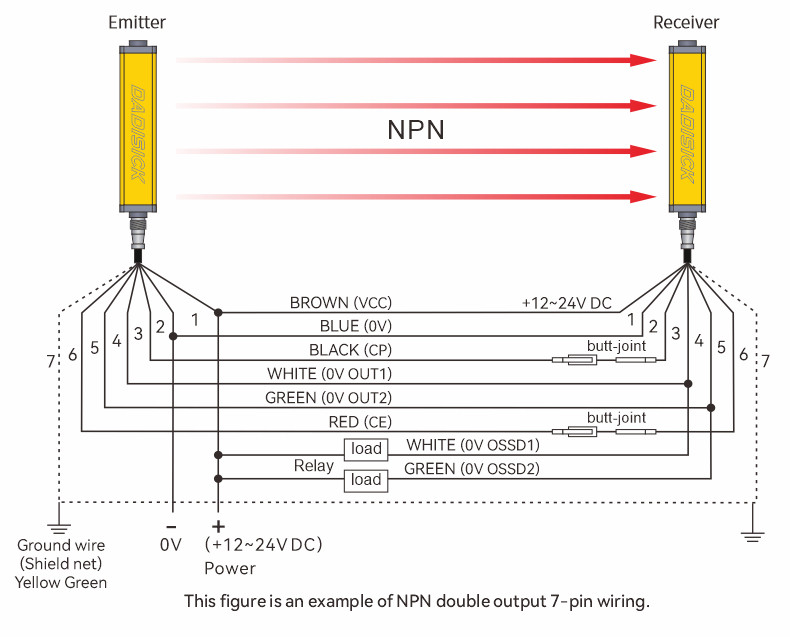

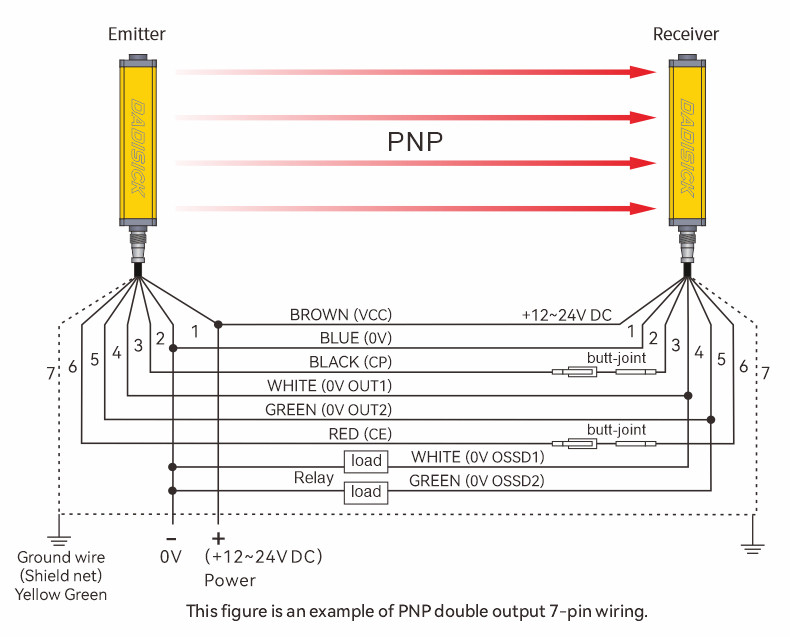

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 / IP67 | IP65 | |

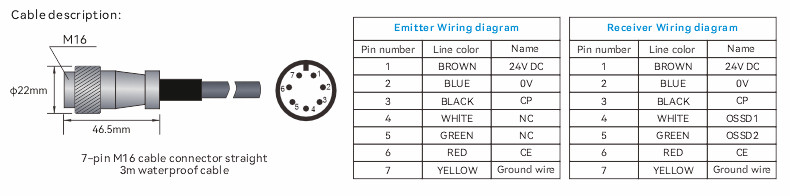

Connector | M12 | M16 | |

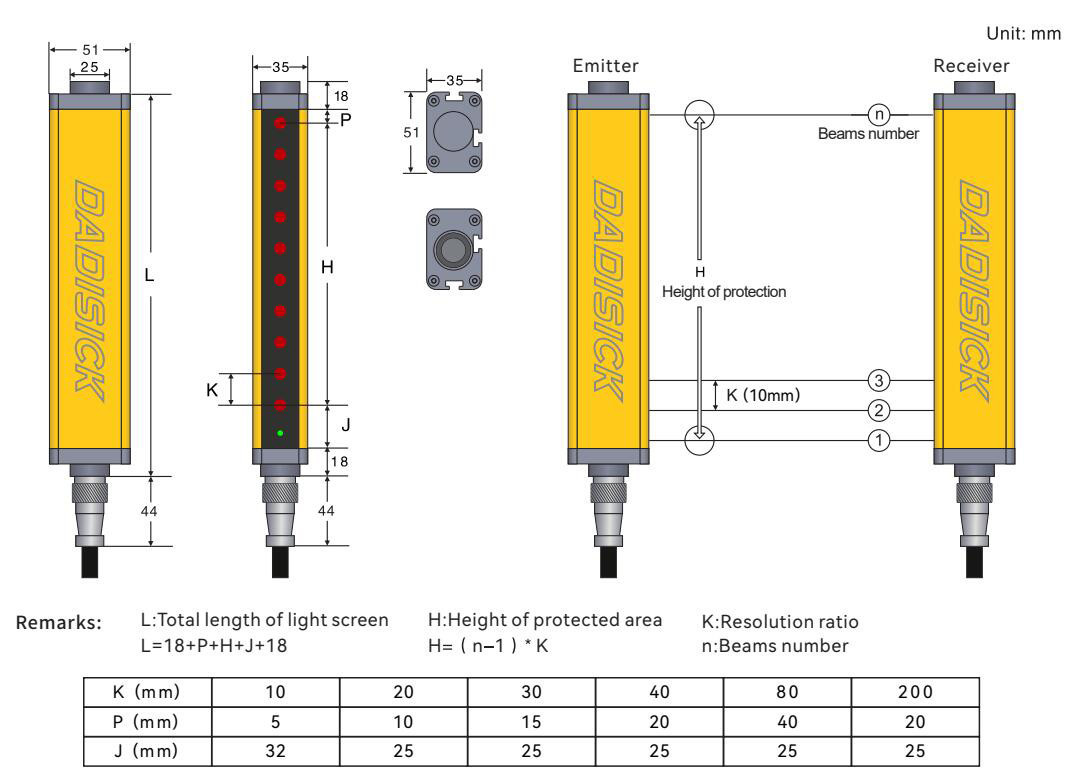

Housing cross-section | 50 mm × 55 mm | 35 mm × 51 mm | |

Safety Certificate | CE, UKCA, TÜV, cULus, RoHS | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand ReeR's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

FAQ

What is the blanking function of a safety light curtain?

The blanking function of a safety light curtain is a feature that temporarily disables or ignores the detection capability of certain areas of the light curtain under specific conditions. This function is commonly used in production lines or machinery that require frequent intervention or movement of objects, to avoid frequent triggering of the light curtain, which could cause machine downtime or work interruptions.

Specifically, the blanking function can be applied in the following ways:

1.Selective Protection of Work Areas: It allows for the movement of materials or operations within specific areas without triggering the light curtain. For example, on a production line where materials frequently pass through the light curtain on a conveyor belt, the blanking function can temporarily disable detection in that area to prevent unnecessary shutdowns.

2.Handling Partial Obstruction of the Curtain: During production, if certain objects partially obstruct the safety light curtain, the blanking function can cause the system to ignore these specific obstructed parts, ensuring continuous operation of the production line.

3.Simplifying Equipment Debugging and Maintenance: During equipment debugging and maintenance, using the blanking function allows technicians to work without completely disabling the safety system, thereby improving efficiency and safety.

There are various methods to implement the blanking function, which can be achieved through hardware or software. For example, by setting parameters on the light curtain controller or using models of light curtains with built-in blanking functions. This function needs to be carefully configured and debugged to ensure it does not compromise overall safety, providing convenience while still safeguarding operators.

Overall, the blanking function enhances the adaptability and flexibility of safety light curtains in complex operational environments, allowing equipment to run more efficiently while maintaining safety.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.