For Turck EZ-SCREEN LS Series Type 4 Heavy-Duty Safety Light Curtain Replacement 8-pin M12 Pigtail QD 23 mm Resolution | 12 m Operating Range | 1470 mm to 1820 mm Protective Height

- Model

- EZ-SCREEN LS Series | SLLCP23-1470P88, SLLCP23-1540P88, SLLCP23-1610P88, SLLCP23-1680P88, SLLCP23-1750P88, SLLCP23-1820P88, SLLCR23-1470P8, SLLCR23-1540P8, SLLCR23-1610P8, SLLCR23-1680P8, SLLCR23-1750P8, SLLCR23-1820P8, SLLCE23-1470P8, SLLCE23-1540P8, SLLCE23-1610P8, SLLCE23-1680P8, SLLCE23-1750P8, SLLCE23-1820P8

Item specifics

- Series:

- EZ-SCREEN LS Series

- Resolution:

- 23 mm

- Scanning range:

- 0.1 m - 12 m

- Protective field height:

- 1470 mm - 1820 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 22.6 ms - 26.9 ms

- Connection type:

- M12

- Security level:

- PLe4

Review

Description

For Turck EZ-SCREEN LS Series Type 4 Heavy-Duty Safety Light Curtain Replacement Parameter

Pair | Receiver | From network | DADISICK |

SLLCP23-1470P88 | SLLCR23-1470P8 |

SLLCE23-1470P8 | QMT74-20-1460-2BD |

SLLCP23-1540P88 | SLLCR23-1540P8 | SLLCE23-1540P8 | QMT78-20-1540-2BD |

SLLCP23-1610P88 | SLLCR23-1610P8 | SLLCE23-1610P8 | QMT82-20-1620-2BD |

SLLCP23-1680P88 | SLLCR23-1680P8 | SLLCE23-1680P8 | QMT84-20-1660-2BD |

SLLCP23-1750P88 | SLLCR23-1750P8 | SLLCE23-1750P8 | QMT88-20-1740-2BD |

SLLCP23-1820P88 | SLLCR23-1820P8 | SLLCE23-1820P8 | QMT92-20-1820-2BD |

Beam spacing | 23 mm | 20 mm | |

Protected altitude | 1470 mm, 1540 mm, 1610 mm, 1680 mm, 1750 mm, 1820 mm | 1460 mm, 1540 mm, 1620 mm, 1660 mm, 1740 mm, 1820 mm | |

Scanning range | 0.1 m - 12 m | 0.3 m - 15 m | |

Response time | 22.6 ms - 26.9 ms | ≤15 ms | |

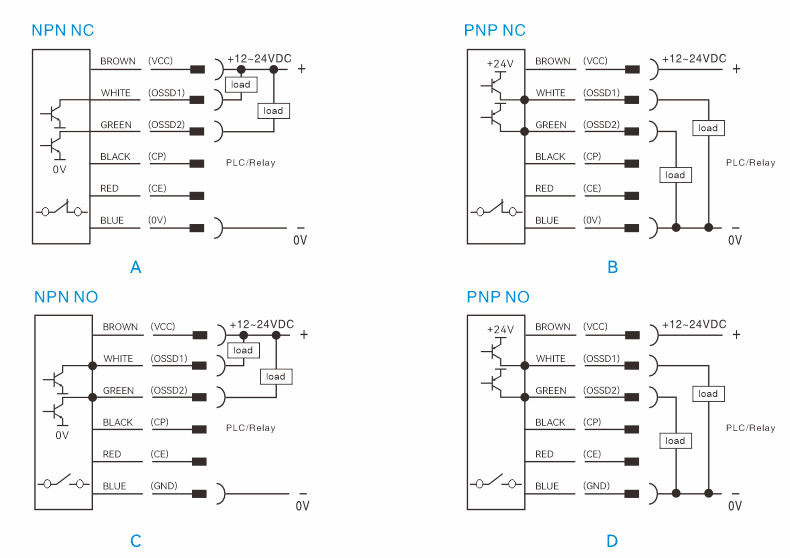

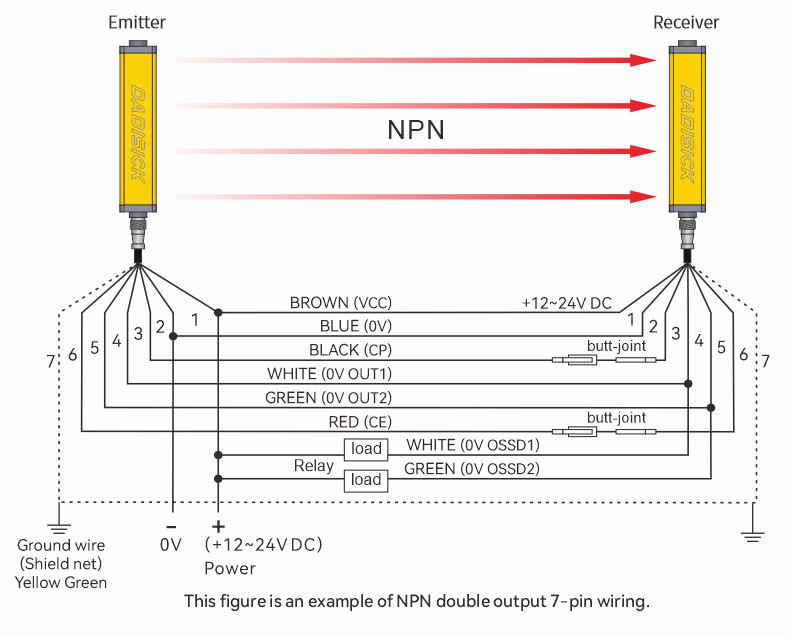

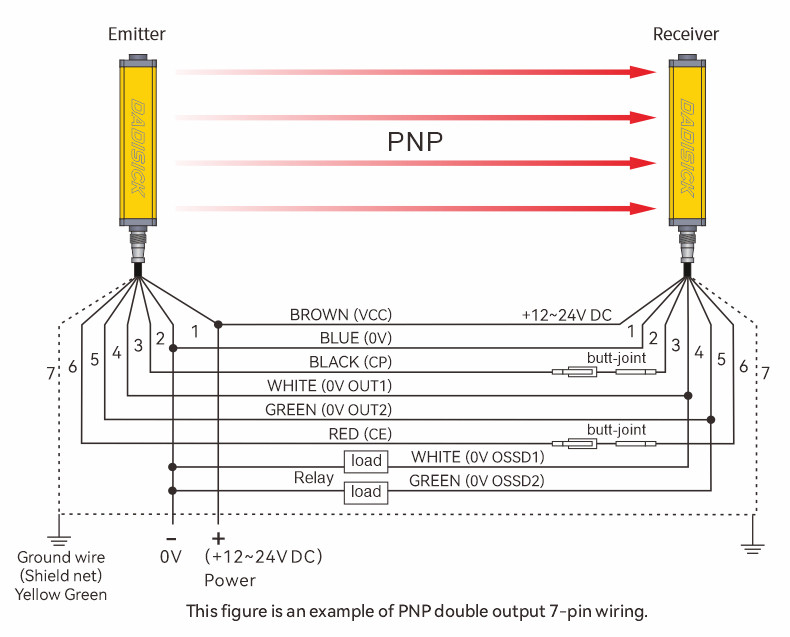

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 / IP67 | IP65 | |

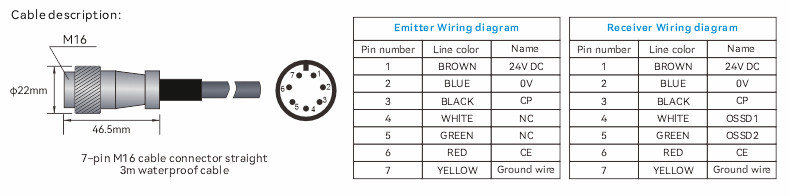

Connector | M12 | M16 | |

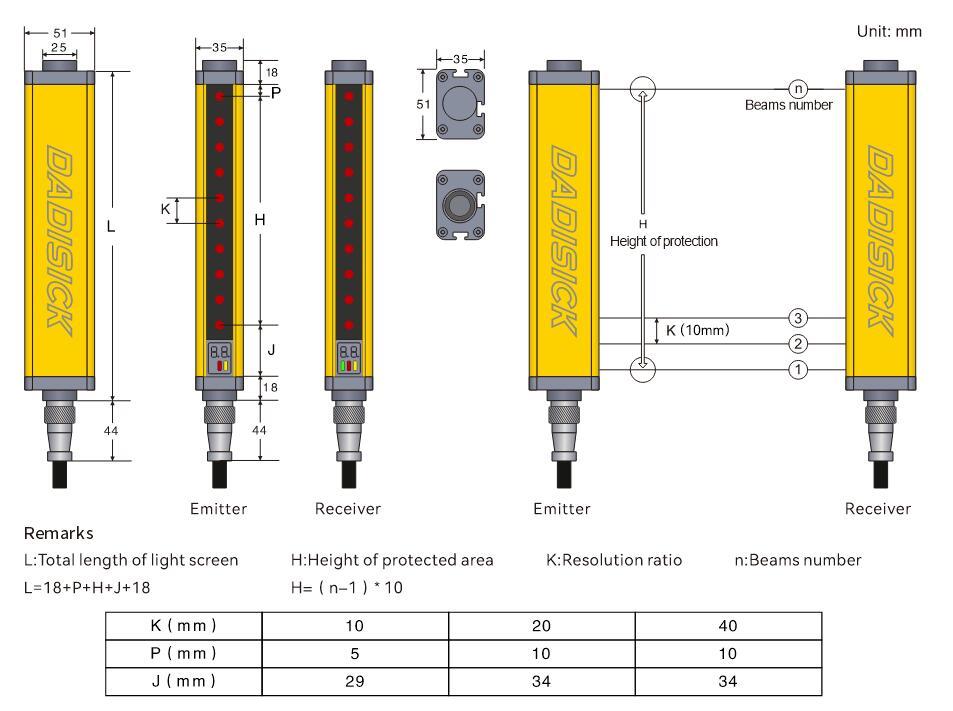

Housing cross-section | 45 mm × 36 mm | 35 mm × 51 mm | |

Safety Certificate | cULus, CE | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand Turck's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

QMT series safety light curtain

Model:

QMT74-20-1460-2BD, QMT78-20-1540-2BD, QMT82-20-1620-2BD, QMT84-20-1660-2BD, QMT88-20-1740-2BD, QMT92-20-1820-2BD

FAQ

What are the requirements for the working environment of safety light curtains?

The requirements for the working environment of safety light curtains include:

1.Temperature: The environmental temperature should be within the range of -10℃ to 55℃. Excessive temperatures, either too high or too low, may affect the normal operation of the safety light curtain.

2.Humidity: The air relative humidity should not exceed 95%. High humidity may cause condensation on the optical components, affecting their performance.

3.Media: The air should be free of media that can trigger explosions or corrode metals and damage insulation.

4.Vibration: The vibration amplitude and corresponding frequency should conform to national standards. Excessive vibration may damage internal components of the safety light curtain.

5.Lighting: Direct sunlight or other strong light sources should be avoided, as they may interfere with the detection accuracy of the safety light curtain.

6.Dust and dirt: Environments with excessive dust or dirt may accumulate on the optical surfaces of the safety light curtain, reducing its transmission efficiency. Regular cleaning and maintenance are required.

7.Reflective surfaces: Surfaces that can reflect light should be avoided in the vicinity of the safety light curtain, as reflected light may interfere with its operation.

8.Interference sources: The installation location should be free of interference sources that can affect the signal transmission of the safety light curtain, such as electromagnetic fields.

9.Space: The installation space should allow for the correct alignment and adjustment of the transmitter and receiver units of the safety light curtain.

It is important to note that the specific requirements for the working environment of safety light curtains may vary depending on the model, manufacturer, and intended application. It is recommended to consult the manufacturer's specifications and installation instructions for detailed information.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.