For Turck EZ-SCREEN LP Series Type 4 Compact Safety Light Curtain Replacement Cascade Models 8-pin M12 Pigtail QD 25 mm Resolution | 7 m Operating Range | 410 mm to 1390 mm Protective Height

- Model

- EZ-SCREEN LP Series | SLPCP25-410P88, SLPCP25-550P88, SLPCP25-690P88, SLPCP25-830P88, SLPCP25-970P88, SLPCP25-1110P88, SLPCP25-1250P88, SLPCP25-1390P88, SLPCR25-410P8, SLPCR25-550P8, SLPCR25-690P8, SLPCR25-830P8, SLPCR25-970P8, SLPCR25-1110P8, SLPCR25-1250P8, SLPCR25-1390P8, SLPCE25-410P8, SLPCE25-550P8, SLPCE25-690P8, SLPCE25-830P8, SLPCE25-970P8, SLPCE25-1110P8, SLPCE25-1250P8, SLPCE25-1390P8,

Item specifics

- Series:

- EZ-SCREEN LP Series

- Resolution:

- 25 mm

- Scanning range:

- 0.1 m - 7 m

- Protective field height:

- 410 mm - 1390 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 9.5 ms - 20 ms

- Connection type:

- M12

- Security level:

- PLe4

Review

Description

For Turck EZ-SCREEN LP Series Type 4 Compact Safety Light Curtain Replacement Parameter

Pair | Receiver | Emitter | DADISICK |

SLPCP25-410P88 | SLPCR25-410P8 |

SLPCE25-410P8 | QO22-20-420-2BB |

SLPCP25-550P88 | SLPCR25-550P8 | SLPCE25-550P8 |

QO28-20-540-2BB |

SLPCP25-690P88 | SLPCR25-690P8 | SLPCE25-690P8 | QO36-20-700-2BB |

SLPCP25-830P88 | SLPCR25-830P8 | SLPCE25-830P8 | QO42-20-820-2BB |

SLPCP25-970P88 | SLPCR25-970P8 | SLPCE25-970P8 | QO50-20-980-2BB |

SLPCP25-1110P88 | SLPCR25-1110P8 | SLPCE25-1110P8 | QO56-20-1100-2BB |

SLPCP25-1250P88 | SLPCR25-1250P8 | SLPCE25-1250P8 | QO64-20-1260-2BB |

SLPCP25-1390P88 | SLPCR25-1390P8 | SLPCE25-1390P8 | QO70-20-1380-2BB |

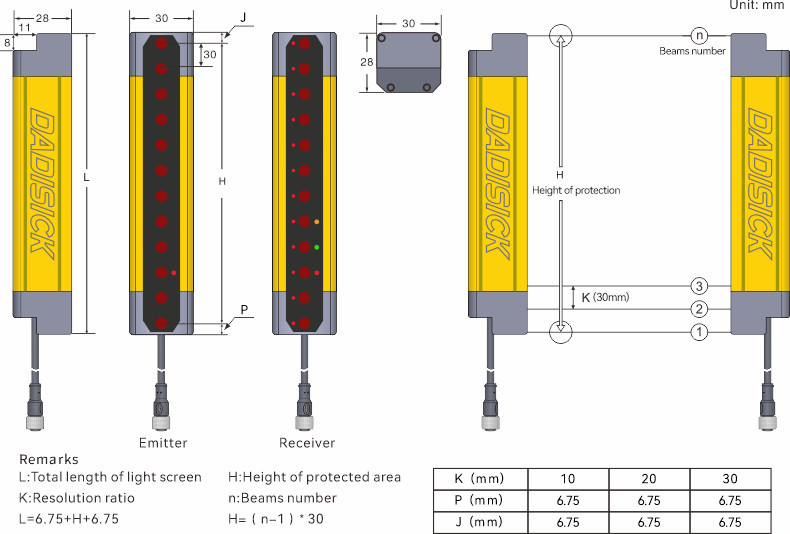

Beam spacing | 25 mm | 20 mm | |

Protected altitude | 410 mm, 550 mm, 690 mm, 830 mm, 970 mm, 1110 mm, 1250 mm, 1390 mm | 420 mm, 540 mm, 700 mm, 820 mm, 980 mm, 1100 mm, 1260 mm, 1380 mm | |

Scanning range | 0.1 m - 7 m | 0.3 m - 6 m | |

Response time | 9.5 ms - 20 ms | ≤15 ms | |

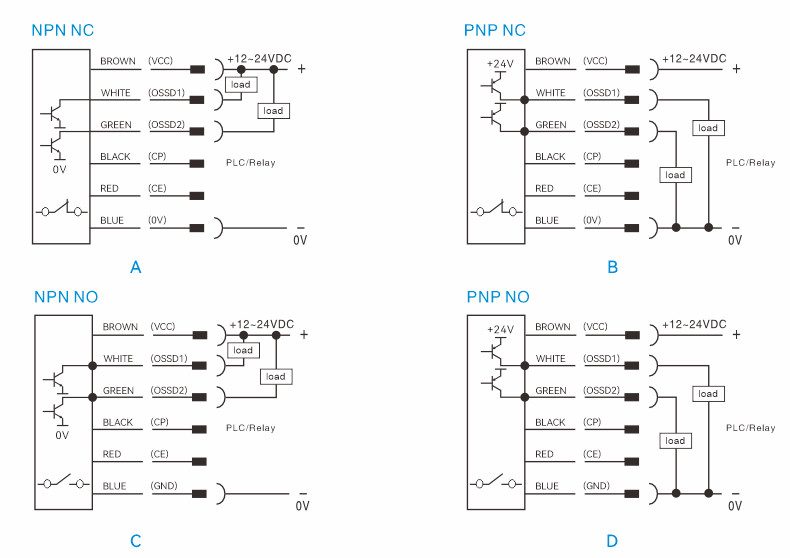

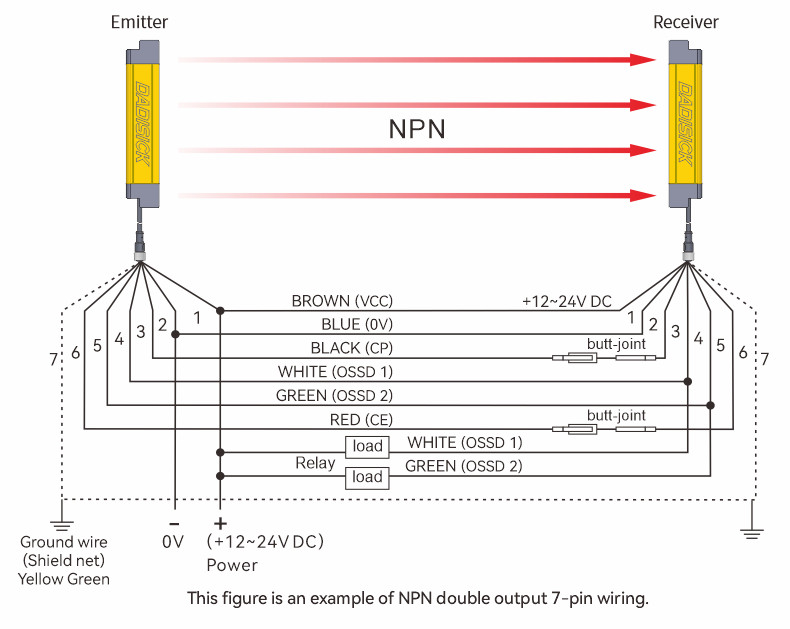

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

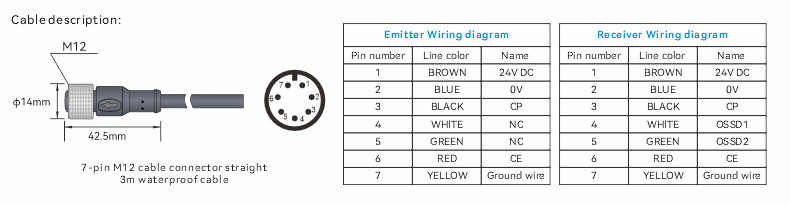

Connector | M12 | M12 | |

Housing cross-section | 28 mm × 26 mm | 30 mm × 28 mm | |

Safety Certificate | CE | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand Turck's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QO22-20-420-2BB, QO28-20-540-2BB, QO36-20-700-2BB, QO42-20-820-2BB, QO50-20-980-2BB, QO56-20-1100-2BB, QO64-20-1260-2BB, QO70-20-1380-2BB

FAQ

How does the performance of safety light curtains hold up under conditions such as dust, moisture, and other environmental factors?

The protection level (IP code) of safety light curtains is an important indicator, representing the product's ability to resist dust and water. For applications with harsh environmental conditions, safety light curtains with higher protection levels can be selected to ensure they can withstand dust and moisture to a certain extent. Generally, the higher the protection level, the better the performance of the light curtains in harsh environments.

However, even with a higher protection level, safety light curtains may still be affected by factors such as dust and moisture. For example, excessive dust or dirt covering the light curtains may block some beams, leading to a decrease in detection accuracy. Additionally, moisture may cause the internal electronic components of the light curtains to become damp, thereby affecting their performance.

To address these challenges, some measures can be taken to improve the performance of safety light curtains in harsh environments. For instance, regularly clean the surface of the light curtains to ensure they are in good working condition; in humid environments, choose light curtains with moisture-resistant features or implement other moisture-proof measures; in environments with a lot of dust, select light curtains with dust-proof features or add dust covers and other protective measures.

Furthermore, the design and selection of safety light curtains are also crucial. When selecting, choose light curtains with appropriate parameters such as resolution, detection distance, and response time based on the actual application requirements. Additionally, consider factors such as the communication interface, ease of installation and maintenance to ensure they can be effectively integrated with other equipment and reduce the operating costs of the system.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.