For RIKEN OPTECH RFG414 Series 10 mm Resolution 10 m Sensing Distance 710 mm to 1910 mm Protective Height Extended Light Curtain Replacement

- Model

- RFG414 Series | RFG414-780FL2, RFG414-980FL2, RFG414-1180FL2, RFG414-1380FL2, RFG414-1580FL2, RFG414-1780FL2, RFG414-1980FL2

Item specifics

- Series:

- RFG414 Series

- Resolution:

- 10 mm

- Scanning range:

- 0.3 - 10 m

- Protective field height:

- 710 - 1910 mm

- 2 Safety outputs (OSSD):

- 2 PNP

- Response time:

- 10 - 21 ms

- Connection type:

- M12

- security level:

- PLe4

Review

Description

For RIKEN OPTECH RFG414 Series 10 mm Resolution 10 m Sensing Distance 710 mm to 1910 mm Protective Height Extended Light Curtain Replacement Parameter

Brand | From network | DADISICK |

|

|

Models

|

RFG414-780FL2 | QMT72-10-710 2BC |

|

RFG414-980FL2 |

QMT92-10-910 2BC | ||

RFG414-1180FL2 | QMT112-10-1110 2BC |

||

RFG414-1380FL2 | QMT132-10-1310 2BC | ||

RFG414-1580FL2 | QMT152-10-1510 2BC | ||

RFG414-1780FL2 | QMT172-10-1710 2BC | ||

RFG414-1980FL2 | QMT192-10-1910 2BC | ||

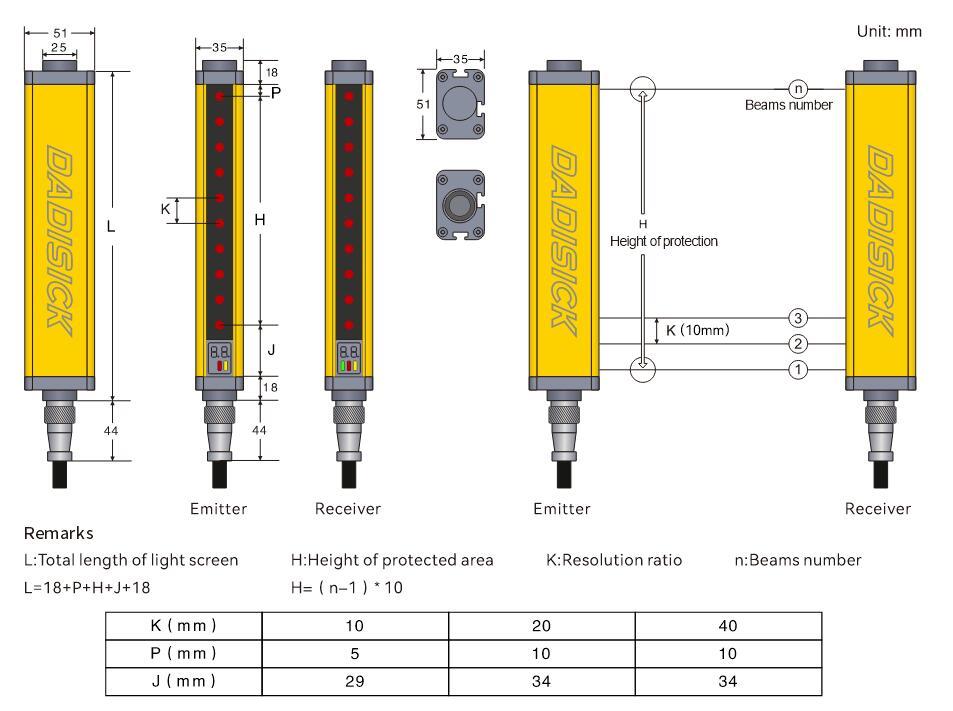

Beam spacing | 10 mm | 10 mm | |

Protected altitude | 710 mm, 910 mm, 1110 mm, 1310 mm, 1510 mm, 1710 mm, 1910 mm | 710 mm, 910 mm, 1110 mm, 1310 mm, 1510 mm, 1710 mm, 1910 mm | |

Scanning range | 0.3 - 10 m | 0.3 - 10 m | |

Response time | 10 ms - 21 ms | ≤15 ms | |

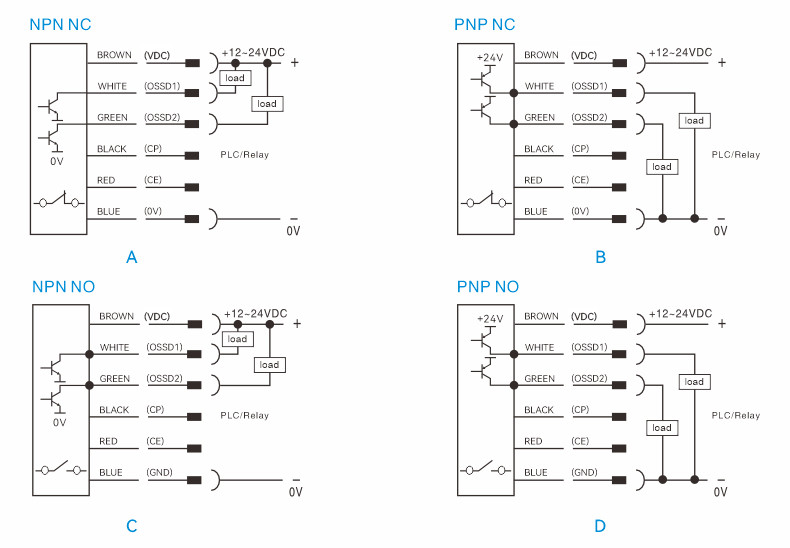

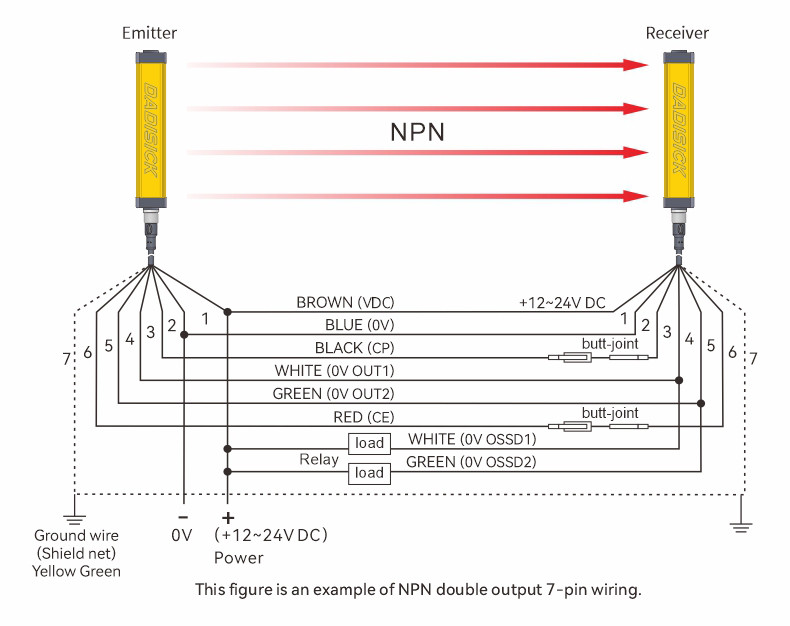

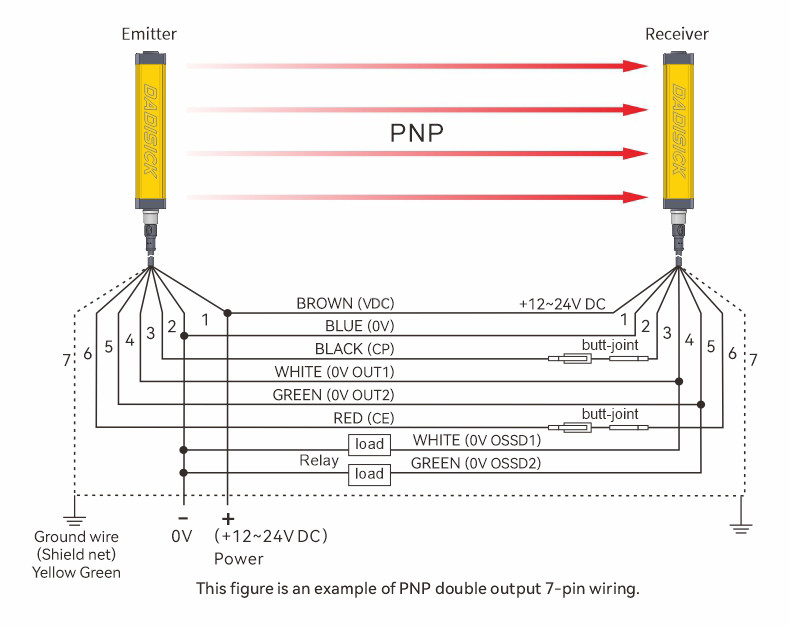

Output method | 2 PNP | 2 PNP | |

Reliability and durability | IP65 | IP65 | |

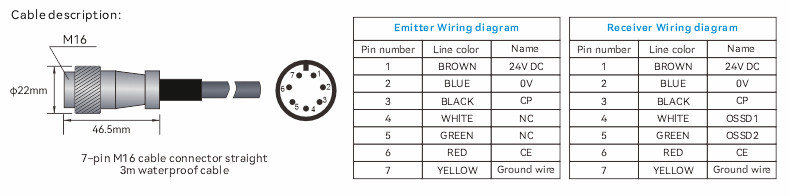

Connector | M12 | M16 | |

Housing cross-section | 32 mm x 38 mm | 51 mm x 35 mm | |

Safety Certificate | CE, UL | TÜV, UL, CE, RoHS, GB | |

We are able to reproduce the specific connection configuration of each brand with high level of accuracy. | |||

Product model display instructions

The brands and specifications shown on this page are for product selection only. Our safety light curtain is a safety part made by DADISICK, not official brand RIKEN OPTECH's products. DAIDSICK offer replacement for official brand products. We are not the owner of the brands. If you need to buy official brand products, please contact the brand official representative.

Product recommendations

Model:

QMT72-10-710 2BC, QMT92-10-910 2BC, QMT112-10-1110 2BC

QMT132-10-1310 2BC, QMT152-10-1510 2BC, QMT172-10-1710 2BC

QMT192-10-1910 2BC

FAQ

Q: What to do when a safety light curtain malfunctions?

A:

Safety light curtains are important safety devices used to protect workers and equipment. However, even high-quality safety light curtains may experience malfunctions. This article will discuss common safety light curtain malfunctions and provide troubleshooting solutions to help you resolve the issues promptly.

1. Safety light curtain not functioning properly

If the safety light curtain is not functioning properly, first check if the power supply is working correctly. Ensure that the power cable is connected properly and check if the indicator lights on the light curtain are illuminated. If the indicator lights are on, it may indicate a power supply issue that requires either replacing the power supply or repairing the power cable.

Additionally, check the connection between the emitter and receiver of the light curtain to ensure it is secure. Sometimes, the connection may become loose or disconnected, resulting in the failure to transmit light signals. Reconnect the emitter and receiver, ensuring a secure connection.

2. False alarms from safety light curtain

If the safety light curtain is frequently producing false alarms, meaning it signals an alert even when no objects or personnel are entering, it may be experiencing interference. First, check the surrounding environment for any reflective objects or bright light sources. These objects or light sources can interfere with the proper operation of the light curtain.

Additionally, check if there are any obstacles blocking the transmission of light between the emitter and receiver of the light curtain. If there are objects or dust obstructing the transmission of light, remove them or reinstall the light curtain to ensure smooth light transmission.

3. Sensitivity issues with safety light curtain

If the sensitivity of the safety light curtain is either too high or too low, meaning it fails to produce an alert signal when obstacles are present, it may require adjusting the sensitivity settings. Refer to the user manual of the light curtain to learn how to adjust its sensitivity.

While adjusting the sensitivity, you can try gradually increasing or decreasing the sensitivity settings until you achieve the desired alert effect. If the issue persists, it may be necessary to check if the receiver of the safety light curtain is damaged or needs replacement.

For more complex malfunctions, it is recommended to seek assistance from professional technical support personnel for inspection and repair. They have extensive experience and expertise that can help you quickly resolve the issues with your safety light curtain.

In summary, when a safety light curtain malfunctions, first check if the power supply is working properly, and ensure that the connection between the light emitter and receiver is secure. If there are false alarms or sensitivity issues, settings can be adjusted or obstructions can be cleared. For complex malfunctions, it is recommended to seek professional technical support. Ensuring the proper functioning of the safety light curtain is crucial for protecting the safety of workers and equipment.

Disclaimers

The product model information provided on this website is sourced from public channels, aiming to provide users with reference for product comparison and selection. This website does not guarantee the accuracy, completeness, or reliability of information, nor does it constitute a recommendation or recognition of any brand or company. Users should verify and bear corresponding risks when using the information provided on this website. This website shall not be liable for any loss or damage caused by the use of information on this website.