What Is a Safety Edge?

- Share

- publisher

- Zoe

- Issue Time

- Oct 31,2024

Summary

The safety edge (also known as a safety bumper) is designed to prevent shearing and crushing injuries by detecting any obstacles or pressure to immediately stop operation, thus preventing harm. Safety edges are one of the essential solutions for preventing accidents and injuries in public, industrial, and automated environments.

What Is a Safety Edge?

Safety edge (also known as safety bumper) is an essential safety device to prevent shearing and crushing injuries. They detect any obstacles or applied pressure to immediately halt operation, thereby preventing harm. Safety edges are indispensable solutions for preventing accidents and injuries in public, industrial, and automated environments. These sensitive strips are typically installed along the edges of moving machinery or equipment to protect personnel from the hazards of automatic doors (such as those in public areas and factories) and CNC machine doors. By using physical contact or pressure sensing technology to detect obstacles, they trigger a stop mechanism, ensuring safe operation.

Why Do You Need a Safety Edge?

Safety edges play a crucial role in automated equipment and machinery. Their primary purpose is to prevent injuries caused by contact with moving parts, such as pinching, shearing, or crushing injuries.

◾ Injury Prevention: When a person or object comes into contact with equipment equipped with a safety edge, it quickly detects the contact and triggers a safety mechanism, immediately stopping or reversing the device’s movement. This greatly reduces the likelihood of accidents, protecting both operators and nearby personnel.

◾ Supplement to Risk Assessment: While risk assessments are essential for determining the need for safety edges, safety edges themselves provide an additional layer of protection. Even if a risk assessment does not foresee all potential risks, safety edges can offer immediate protection during real-world operation.

◾ Enhancing Overall Equipment Safety: Installing safety edges on automated doors, platforms, or other machinery enhances the safety and reliability of these devices. They are a key component of the overall safety system, helping to ensure that equipment does not pose a risk to individuals during normal operation.

◾ Compliance with Regulations and Standards: In many countries and regions, safety edges are required by regulations and standards for certain types of automated equipment and machinery. This helps ensure that the equipment meets safety standards and reduces legal risks associated with non-compliance.

Typical Applications of Safety Edges:

◾ Rigid Chain Lifts and Hydraulic Lifts

Safety edges can be mounted on the edges of lifting devices such as rigid chain lifts and hydraulic lifts. When personnel or objects come into contact with the safety edge, it triggers a switch that stops the lift, thereby preventing potential hazards such as pinching, shearing, or falling. Installing safety edges at the entrances and along the runways of these lifts can effectively prevent accidents and ensure the safety of both personnel and equipment.

◾ Tire Production Line: Tire Molding Machine

In the tire production line, particularly around the tire molding machine, safety edges serve as crucial safety protection devices. When operators or other objects approach the machine, the safety edge can quickly detect this and immediately stop the machine's movement, reducing the likelihood of personal safety incidents. This application not only enhances the production efficiency of the tire line but also ensures the safety of operators.

◾ AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots)

AGVs and AMRs are widely used in automated warehousing and logistics. These vehicles often need to navigate and avoid obstacles in complex environments. As a basic safety configuration for these vehicles, safety edges provide additional protection. When AGVs or AMRs encounter obstacles or personnel, the safety edge can quickly trigger a switch to stop the vehicle, avoiding collisions and injuries. Furthermore, safety edges can be used in conjunction with radar, vision cameras, and other safety sensors for more comprehensive and reliable safety protection.

◾ Automatic Machine Doors, Electric Doors, and Elevator Doors

Installing safety edges on automatic machine doors, electric doors, and elevator doors ensures that the doors stop or reverse upon encountering obstacles during the closing process. This application effectively prevents injuries to personnel or damage to equipment, particularly in elevator doors, where the application of safety edges is crucial for passenger safety.

How to Choose the Right Safety Edge?

1️⃣ Safety Level Requirements: Choose safety edges that meet the corresponding safety standards based on the safety needs of the application scenario. For example, DADISICK's DB-PSE series, in combination with the QSRN and Ter-A series safety relays, complies with the following standards: EN1760-2, ISO13856-2, EN62061, EN ISO13849-1, IEC61508, and EN60204-1.

2️⃣ Environmental Adaptability: Consider whether the safety edge can adapt to complex working environments, such as humidity or salt spray. The DB-PSE series safety edges are designed to withstand harsh environments, featuring a surface protective layer made of EPDM rubber and CR rubber, with an aluminum groove base to prevent sliding parts.

3️⃣ Pressure Switch Lifespan: Select pressure switches with a long lifespan to reduce maintenance and replacement frequency. The pressure switches in the DB-PSE series safety edges have a lifespan of up to 3 million cycles.

4️⃣ Resistance and Consistency: Choose ultra-low resistance alloy pressure switches to achieve highly consistent performance.

5️⃣ Length and Customization: Select the appropriate length of safety edge according to the specific dimensions and shapes of the equipment. The DB-PSE series offers safety edges ranging from 200mm to 6000mm and supports customized installation.

6️⃣ Safety Edge Unit Matching: Safety edges should be matched with appropriate safety relays to form a control area. Each control unit can consist of a single safety edge or multiple safety edges connected in series. Multiple safety edges can be connected in series, but the maximum length of a control area (including connecting cables) should not exceed 100 meters.

DADISICK DB-PSE Series Safety Edges

Safety Edge Sensor DB-PSE Series

The DB-PSE series is suitable for various applications, featuring low triggering pressure and multiple specifications to choose from. The sensor length ranges from 200mm to 6000mm and can be bent to fit various mechanical protection scenarios. With an IP65 protection rating, it is suitable for a wide range of working environments and has a mechanical lifespan of over 3 million cycles.

The outer shell is made of EPDM and CR rubber, which can withstand various chemical corrosions, making it suitable for general factory conditions as well as civilian applications. One controller can control up to 10 safety edge sensors connected in series. Additionally, we accept customized products for special installation shapes and sizes.

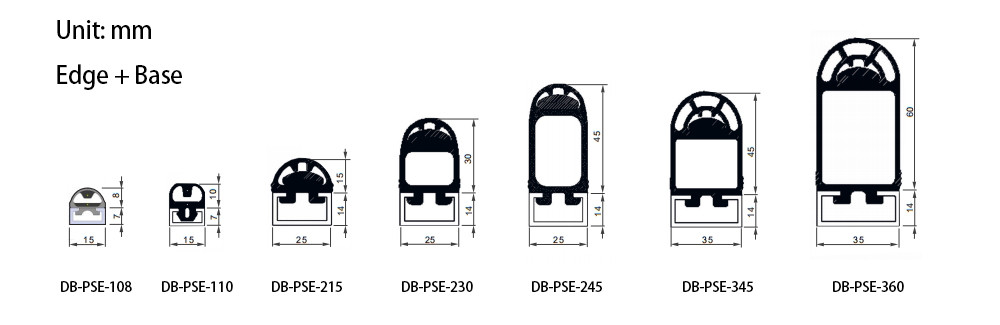

DB-PSE Series Safety Edges Models

Description

Detection Method: Pressure sensing

Maximum Detection Angle: Less than 90°

Trigger Force (depending on specifications and usage): ≥ 25 N - 250 N

Mechanical Lifespan: > 3,000,000 cycles

Surface Protection Material: EPDM rubber, CR rubber

Operating Temperature: -20°C to 55°C

Protection Rating: IP65

Maximum Humidity (at 23°C): 95% (no condensation)

Response Time: 13 ms

|

Models

|

Base width

|

Actuation distance |

Actuation force

|

Overtravel distance

|

Applications (R: Radius of Curvature) | |

|

DB-PSE-108

|

15 mm

|

< 2 mm |

≤ 25 N

|

0

|

Small AGV, R ≥ 50 mm | |

|

DB-PSE-110

|

15 mm

|

< 2 mm |

≤ 25 N

|

0

|

Small AGV, garage access control, industrial applications, etc, R ≥ 150 mm | |

|

DB-PSE-215

|

25 mm

|

< 3 mm |

≤ 25 N

|

0

|

AGV, electric door, industrial applications | R ≥ 300 mm |

DB-PSE-230 | 25 mm | < 3 mm | ≤ 25 N | < 19 mm | R ≥ 450 mm | |

DB-PSE-245 | 25 mm | < 3 mm | ≤ 25 N | < 30 mm | R ≥ 450 mm | |

DB-PSE-345 | 35 mm | < 5 mm | ≤ 100 N | < 30 mm | Large AGV anti-collision, heavy-duty industrial doors, machinery, and industrial applications, R ≥ 600 mm | |

DB-PSE-360 | 35 mm | < 5 mm | ≤ 100 N | < 45 mm | ||

Downloads

Recommended Safety Edge Sensors Replacement

Replacement for | ABB TT-Series Safety Edges | BBC Bircher Smart Access Series | IDEC Safety Edges | OMRON SGE Safety Edges | Rockwell Automation 440F Safedge Safety Edge Profiles | Schmersal SE-P40, SE-P70, STW Series Safety Edges | PEPPERL+FUCHS Safety Edge PSE4 Series | Mayser Safety Edge | ASO Safety Solutions Inc SENTIR edge

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our ultrasonic sensors are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.