TOF LiDAR: A Core Component of Inspection Robots

- Share

- publisher

- Zoe

- Issue Time

- Jul 3,2024

Summary

To ensure inspection robots operate stably in complex and dynamic environments, the choice of obstacle avoidance technology is crucial. DADISICK's LD-05D Series and LD-20D Series TOF LiDAR provide precise obstacle avoidance assurance with their exceptional detection accuracy and anti-interference capabilities, ensuring that inspection robots can perform tasks safely and stably in various environments.

Project Background

High-speed rail stations, as key hubs in the high-speed rail network, handle tens of thousands of passengers and thousands of railcars daily. These stations need to perform detailed inspections on over ten thousand railcars every day, which is undoubtedly a daunting and tedious task. Due to the special requirements of high-speed train operations, inspection work is typically scheduled during the early morning hours to ensure that all necessary checks are completed before the trains begin their daily operations.

However, such a work schedule not only imposes heavy pressure on inspection personnel but may also adversely affect the quality and efficiency of the inspections. Additionally, due to the limitations of manual inspections, some hidden safety hazards are often difficult to detect in a timely manner, potentially posing risks to the safe operation of high-speed trains.

Advantages of Using Inspection Robots

To address the aforementioned issues, it is highly necessary to introduce inspection robots for intelligent inspections. Compared to traditional manual inspections, inspection robots have several distinct advantages:

• Increased Inspection Efficiency: Inspection robots can work continuously 24/7, unaffected by time and weather conditions, significantly enhancing inspection efficiency.

• Reduced Labor Costs: By introducing inspection robots, the number of inspection workers can be greatly reduced, lowering labor costs.

• Improved Inspection Quality: Equipped with high-definition cameras and various sensors, inspection robots can perform more comprehensive and detailed checks on different parts of high-speed trains, identifying hidden safety hazards.

• Real-time Data Transmission: Inspection robots can transmit inspection data in real time to the backend system, facilitating analysis and processing by the staff.

TOF LiDAR: A Core Component of Inspection Robots

To ensure inspection robots operate stably in complex and dynamic environments, the choice of obstacle avoidance technology is crucial. DADISICK's LD-05D Series and LD-20D Series TOF LiDAR provide precise obstacle avoidance assurance with their exceptional detection accuracy and anti-interference capabilities, ensuring that inspection robots can perform tasks safely and stably in various environments.

In the application of inspection robots, DADISICK laser radar can perform the following functions:

• Accurate Obstacle Avoidance: DADISICK laser radar can perceive the surrounding environment of the robot in real-time, including stationary obstacles and moving pedestrians. By accurately calculating the distance and speed of target objects, the robot can quickly make obstacle avoidance decisions, ensuring no collision accidents occur during the inspection process.

• Real-time Data Transmission: DADISICK laser radar can also transmit the acquired environmental and target object information to the robot's backend system in real-time. During the inspection process, the robot can monitor and analyze the distance to surrounding obstacles in real-time, avoiding collisions with obstacles or people and further improving the quality and efficiency of the inspection work.

|

Technical data

|

LD-05D |

LD-20D

|

||

|

Working principle

|

2D TOF |

|||

IO output | NPN or PNP | |||

Work area | 0.05 m ~ 5 m | 0.05 m ~ 20 m | ||

|

Laser source

|

905 nm (class I) |

|||

|

Aperture angle

|

270° |

|||

Scanning frequency | 15 Hz / 30 Hz | |||

Angular resolution | 0.1° / 0.3° | |||

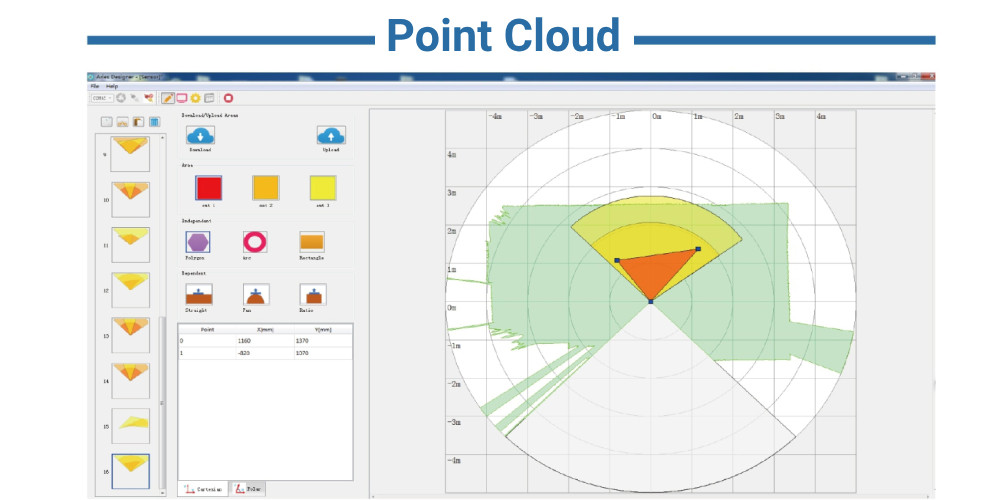

Self-learning function | Automatically scan the environment and generate areas | |||

Electrical connections | Db15 Male / Scatter | |||

Supply voltage | DC 9 V ~ 28 V | |||

Power consumption | 2 W | |||

Switch drive | DC 30 V 50 mA max. | |||

Shell color | Yellow | |||

Enclosure rating | IP65 | |||

Weight | 150 g (cable not included) | |||

Dimensions (L × W × H) | 50 × 50 × 76 mm | |||

Detectable object shape | Almost any shape | |||

Measurement error | ±30 mm | ±30 mm | ||

Number of field sets | 16 fields, 3 simultaneous protective fields (per field set) | |||

Connection type | Micro-USB | |||

Input | GND/NC × 4 | |||

Switch output | NPN × 3, device working status; PNP × 3, device working status | |||

Delay time | 100 ms ~ 10,000 ms (configurable), typical value 330 ms | |||

Response time | 15 Hz: 67 ms ~ 29,949 ms (configurable), typical value 134 ms; 30 Hz: 33 ms ~ 29,997 ms (configurable), typical value 66 ms | |||

Status Indicator | Status indicator × 1, area group indicator × 3 | |||

Vibration resistance

| 10 - 55 Hz, amplitude 0.75 mm, XYZ three-axis, 2 hours per axis;

50 - 200 Hz, 196 m/s² (20G), scanning speed 2 min/cycle, XYZ three-axis, 2 hours per axis; | |||

Ambient operating temperature | -10 ℃ ~ +55 ℃ | |||

Storage temperature | -30 ℃ ~ +75 ℃ | |||

Ambient light immunity | >15,000 lux | |||

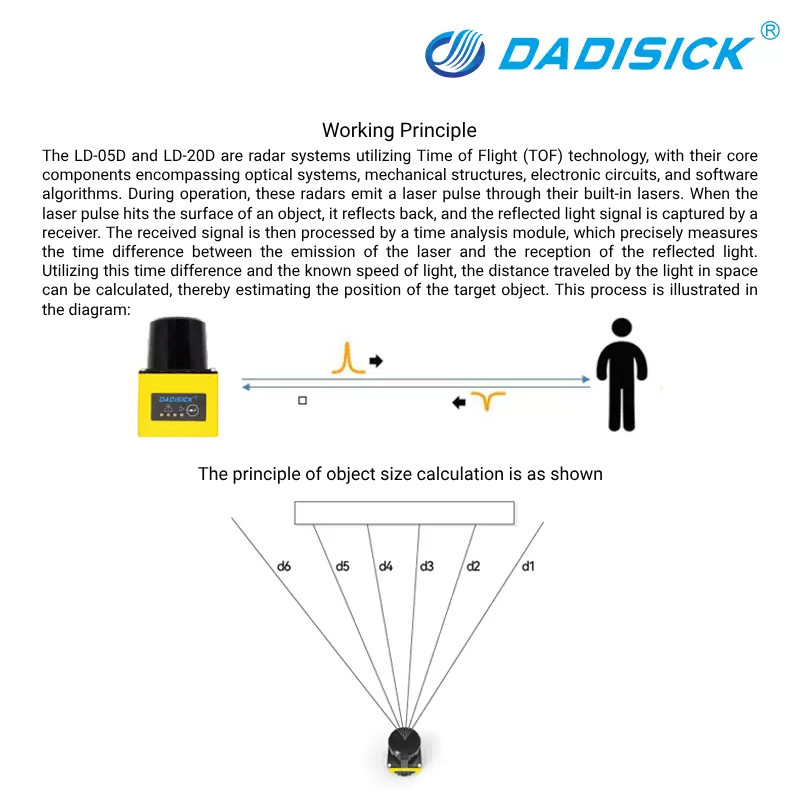

Pulsed Time-of-Flight (TOF) High-Speed Distance Measurement Technology

The LD-05D and LD-20D are radar systems utilizing Time of Flight (TOF) technology, with their core components encompassing optical systems, mechanical structures, electronic circuits, and software algorithms. During operation, these radars emit a laser pulse through their built-in lasers. When the laser pulse hits the surface of an object, it reflects back, and the reflected light signal is captured by a receiver. The received signal is then processed by a time analysis module, which precisely measures the time difference between the emission of the laser and the reception of the reflected light. Utilizing this time difference and the known speed of light, the distance traveled by the light in space can be calculated, thereby estimating the position of the target object. This process is illustrated in the diagram:

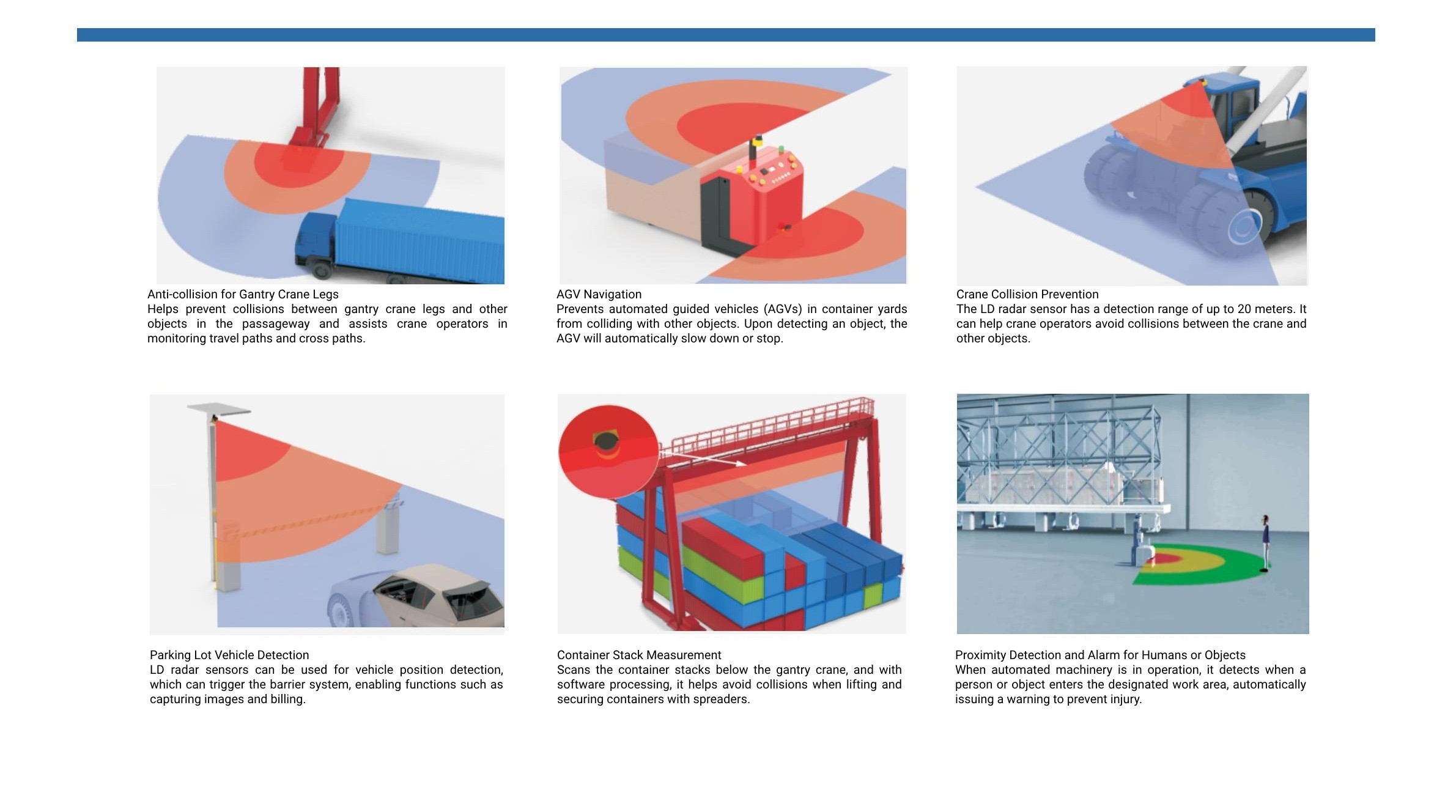

Other Application Scenarios of LiDAR

The successful application of inspection robots at high-speed rail stations is just the tip of the iceberg of the widespread use of LiDAR technology. With continuous technological advancements and the expansion of application scenarios, LiDAR will play an important role in various types of robots.

Industrial Robots: In the industrial sector, LiDAR can help robots achieve precise object recognition, positioning, and gripping functions. By scanning and measuring objects in the working environment, robots can accurately determine the position and orientation of objects, enabling precise operations and processing.

Service Robots: In the service sector, LiDAR can help robots achieve autonomous navigation, path planning, and obstacle avoidance functions. By real-time sensing and understanding of the surrounding environment, service robots can provide users with a more intelligent and convenient service experience.

DADISICK's LiDAR Types: Diverse Choices for More Precise Applications

• Obstacle Avoidance, Navigation, and Obstacle Avoidance + Measurement LiDAR options available

• Scanning angles of 270°/300°/360° available

• Measurement range of 0.05-100 meters with multiple range options

• Maximum scanning frequency of 30Hz

• Micro-USB

• Online output of measurement data (including distance and intensity data in all directions)