Industry Knowledge | The story of ultrasonic sensors starts with a bat...

- Share

- Issue Time

- May 29,2024

Summary

Ultrasonic sensors proximity switch are devices that use sound waves to measure distance. They can emit high-frequency ultrasound and receive reflected sound waves to determine the position and distance of objects. This type of sensor is widely used in various fields, such as automotive reverse radar, industrial measurement, liquid level control, etc.

As early as the 18th century, Italian missionary and biologist Spallanzani discovered that bats rely on a scream (ultrasound) that humans cannot hear to locate obstacles when studying the activities of bats at night. After bats emit ultrasonic waves, they rely on the returned echoes to determine the distance, size, shape and movement of objects.

From the late 19th century to the early 20th century, after the discovery of the piezoelectric effect and the inverse piezoelectric effect in physics, people found a way to use electronics to generate ultrasound, which quickly opened the chapter of the development and promotion of ultrasound technology. In 1922, the definition of ultrasound was first proposed, and ultrasound became a brand new concept. Germany also had the first invention patent for ultrasound therapy.

After being discovered, ultrasound has been widely used in various industries. Since the 20th century, ultrasonic sensors have been widely used in various industries and have become an important category of industrial sensors. This issue will briefly introduce what ultrasonic sensors are and how to use them in industrial production.

What is an Ultrasonic Sensor?

Ultrasonic sensors are sensors that convert ultrasonic signals into other energy signals (usually electrical signals). Ultrasonic waves are mechanical waves with a vibration frequency higher than 20kHz. They have the characteristics of high frequency, short wavelength, small diffraction phenomenon, especially good directionality, and the ability to propagate in a directional manner as rays. Ultrasonic waves have great penetrating power for liquids and solids, especially in solids that are opaque to sunlight. When ultrasonic waves encounter impurities or interfaces, they will produce significant reflections to form reflected echoes, and when they encounter moving objects, they can produce the Doppler effect; they are widely used in industry, national defense, biomedicine, etc.

Working Principle of Ultrasonic Sensor

The basic operation of an ultrasonic sensor is similar to the way bats use echolocation to find insects in flight. The transmitter emits short, high-frequency sound waves, called "chirs," with a frequency between 23 kHz and 40 kHz. When this sound pulse hits an object, some of the sound waves are reflected back to the receiver. By measuring the time interval between the ultrasonic signal being sent and received by the sensor, the distance to the object can be calculated using the following formula.

d=0.5*t*c

Where:

d = distance (meters)

t = time interval between sending and receiving (seconds).

c = speed of sound (343 meters per second).

The simplest ultrasonic sensor is configured with the transmitter and receiver next to each other. This arrangement maximizes the amount of sound that travels in a straight line from the transmitter while reflecting in a straight line to the receiver, helping to reduce measurement errors.

Typical Applications of Ultrasonic Sensors

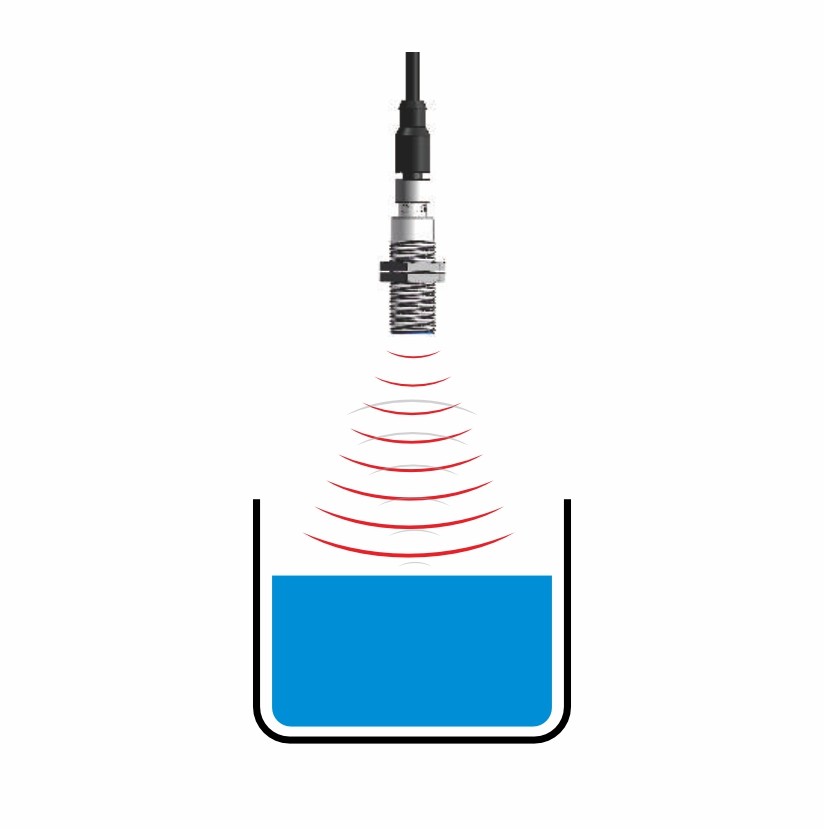

1. Liquid level detection

Liquid level sensing is the most common application of ultrasonic sensors because they can detect liquids of any hue or opacity; in addition, the non-contact detection method does not contact the liquid, so there will be no safety issues when detecting volatile substances.

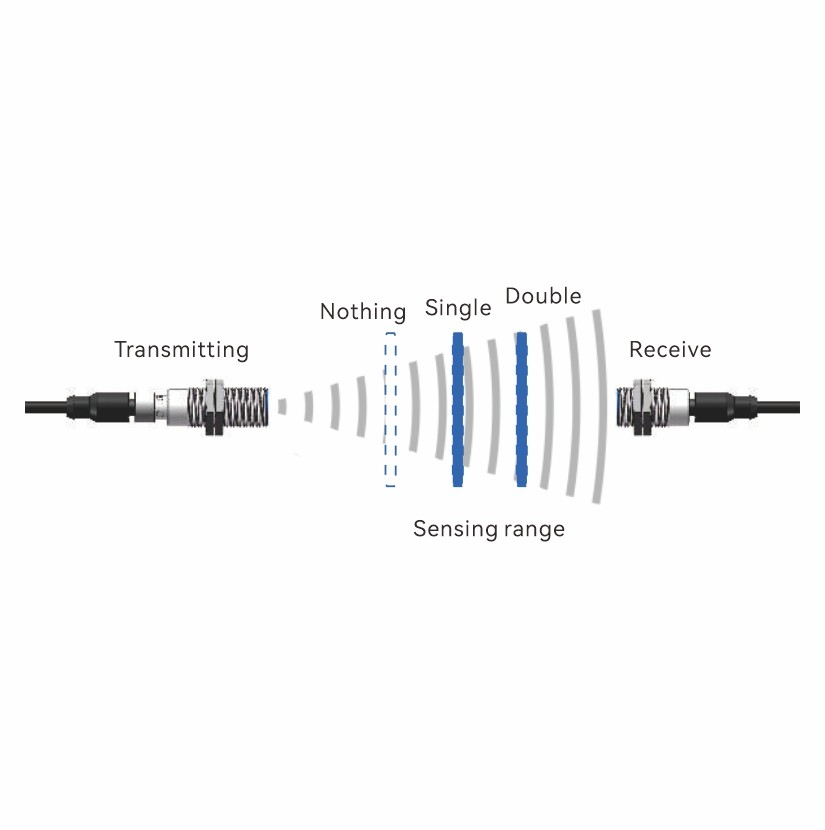

2. Single and double sheet detection

Ultrasonic technology single and double sheet detection sensor is mainly used to detect the single sheet passing through the inspected object and the double sheet and multiple sheet alarm function. It is not limited by the vibration, material and color of the inspected object. It is widely used in paper printing machines, assembly machines, folding machines, packaging machinery, solar cells, silicon wafer manufacturing, labeling, PCB manufacturing, etc.

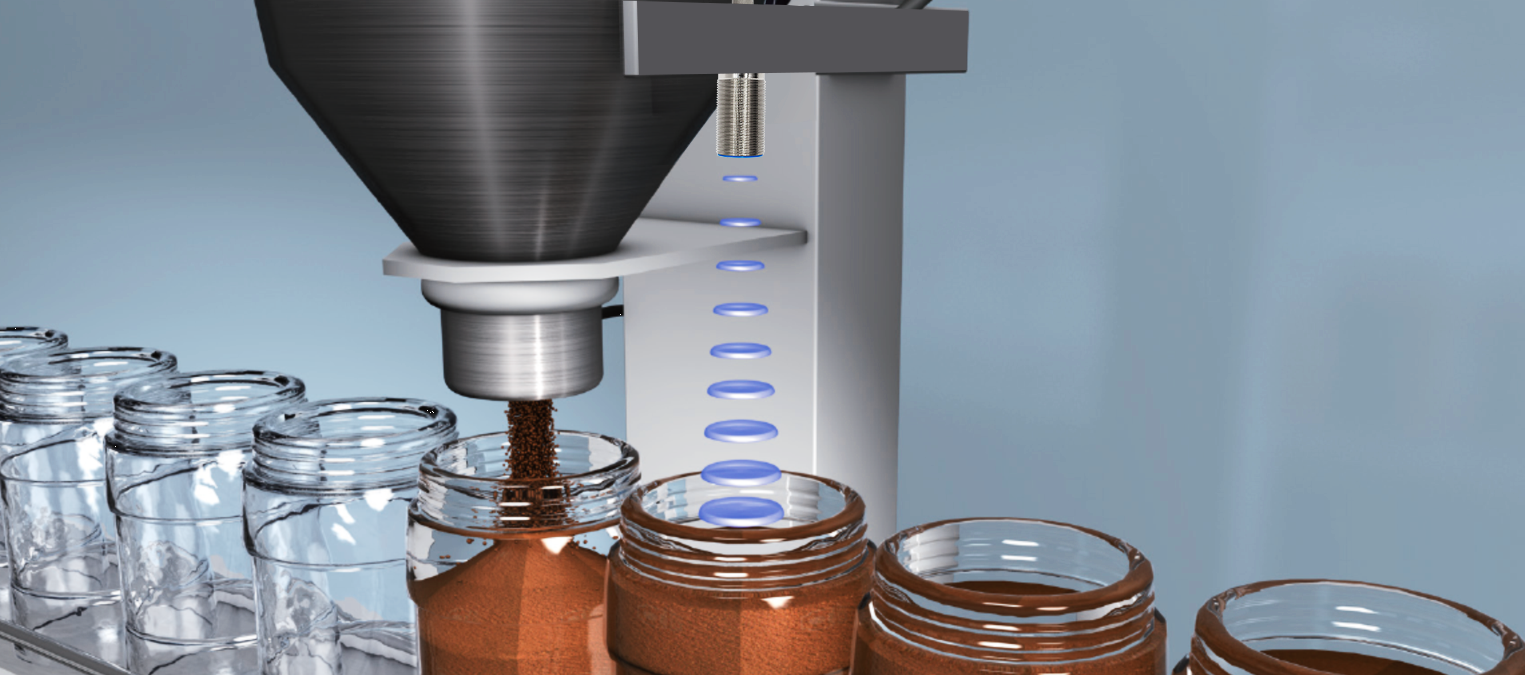

3. General object detection

The other is general object detection, which has the advantages of high cost performance and simplicity. It is widely used in vehicle collision avoidance detection, personnel identification, presence detection, box sorting, forklift pallet detection, bottle counting on beverage filling machines, and object counting on production lines.