Customized Safety Mats: Safeguarding Your Industrial Safety

- Share

- publisher

- Zoe

- Issue Time

- Oct 25,2024

Summary

DADISICK provides custom safety mat solutions. Safety mats are specialized floor mat switches designed for industrial safety protection, also known as safety mats, industrial safety carpets, or safety foot mats. They contain internal circuit switches that, when detecting sufficient pressure, send a signal to the equipment to stop its operation, thereby providing safety protection.

The Importance of Safety Mats in Industrial Automation and Machinery Operations

In industrial environments, employee health and safety are paramount. Safety mats, as an effective protective measure, can significantly reduce the risk of accidents and safeguard operators.

1️⃣ Employee Protection: Safety mats can detect when operators enter hazardous areas, promptly stopping machine operation to effectively protect personnel from harm.

2️⃣ Regulatory Compliance: Many countries and regions require industrial equipment to be equipped with appropriate safety measures. Safety mats are an effective means to comply with these regulations.

3️⃣ Production Efficiency: By reducing downtime and injuries caused by safety incidents, safety mats contribute to increased overall production efficiency.

4️⃣ Risk Management: Safety mats help companies minimize potential safety risks, reducing economic losses and legal liabilities resulting from workplace accidents.

5️⃣ Employee Morale: In a safe work environment, employee satisfaction and morale tend to be higher, which helps reduce turnover rates and boost motivation.

Successful Case of DADISICK Providing Customized Safety Mat Solutions

Customer Background

Oben Group is a diversified international company primarily engaged in the production and sales of plastic products, packaging materials, and sustainable building materials. Their product line includes:

Plastic Products: Plastic films, coatings, thermoformed products, engineering resins, etc., widely used in food packaging and industrial production.

Packaging Materials: Polyester strapping, used for bundling and securing items.

Sustainable Building Materials: Eco-bricks, an environmentally friendly and easy-to-install building material.

In their production process, Oben Group utilizes film extruders to produce polypropylene, polyester, and nylon films, among other products.

Risks During the Extrusion Process and Protective Measures

The extrusion process poses significant risks to employees, such as burns from molten plastic and high temperatures. To address these risks, companies must ensure that screws and other heating devices are adequately protected to prevent potential contact. Additionally, the nozzle connecting the screw tip to the mold must be safeguarded to prevent leaks and avoid the spillage of molten plastic.

Plastic companies should also ensure that any heating, cutting, or sealing processes after extrusion are isolated to minimize burn risks. Given these risks, installing safety mats becomes critically important.

Working Principle of Safety Mats

Safety mats are specialized switch mats designed for industrial safety protection, equipped with circuit switches. When sufficient pressure is detected, they transmit a signal to the equipment, stopping its operation to provide safety protection.

Customer Needs and Solutions

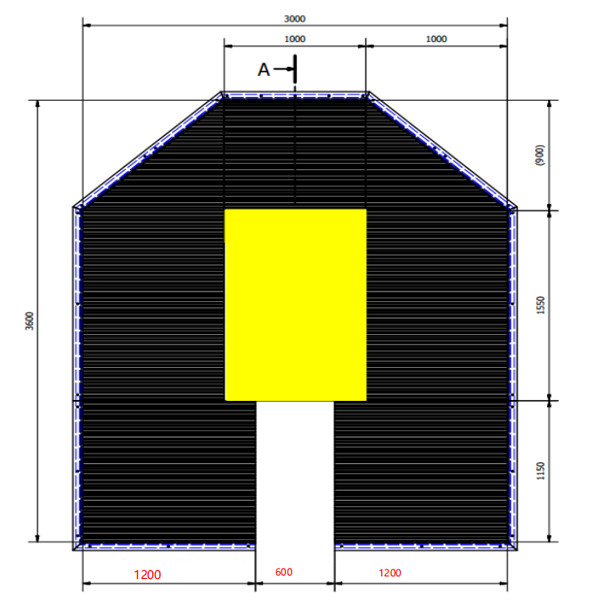

Oben Group sought to replace their old safety mats. We appreciate their trust; after receiving the request and understanding their detailed size and performance requirements, DADISICK's design team used CAD software for precise modeling. We ultimately used high-performance, wear-resistant NBR rubber material combined with advanced anti-slip processing technology to create a durable and safe safety mat product.

We introduced zoned detection technology, dividing the safety mat into multiple independent zones, each with its own alarm conditions and sensitivity settings to meet different safety management needs.

DT14 Series Safety Mat

✅ Detection Range: Detects the presence of personnel and objects.

✅ Recommended Usage: Suitable for mixed areas of personnel and small vehicles for safety protection.

✅ Environmental Requirements: Suitable for indoor and outdoor use, with a temperature range of -10°C to +60°C.

✅ Applicable Industries: Packaging, paper, electronics, automotive welding production lines, forging production lines, general industrial applications, and light to heavy industrial environments such as automated palletizers.

Features

✅ Safety Mat Thickness: 14 mm

✅ Surface Protection Material: NBR rubber

✅ Edge Sealing: Aluminum edge seal

✅ Trigger Force: 30 kg for adults

✅ Load Capacity: Dynamic: 500 kg; Static: 700 kg

✅ Response Time: Less than 30 ms

✅ Slip Resistance Rating: R9

✅ Protection Rating: IP65

✅ Service Life: 1,000,000 activations

✅ Output Type: Normally open

✅ Maximum Voltage: DC 24 V

Notes:

🚩The dimensions of the safety mat refer to the net size excluding the aluminum edging, with a size tolerance of +/- 6 mm.

🚩Custom non-standard size safety mats are accepted, with a maximum single side length of <3000 mm and area ≤ 1.5 m².

🚩Custom designs for irregularly shaped safety mats are accepted; users must provide a floor plan of the protected area and technical requirements. The maximum area for irregularly shaped safety mats is ≤ 3 m².

Testing and After-Sales Service

After producing the safety mats, we conduct rigorous testing before shipment to ensure there are no quality issues. Furthermore, DADISICK provides customers with detailed operation manuals and video tutorials to ensure they can effectively use the safety mats. We have established dedicated after-sales hotlines and technical support teams to promptly address any issues customers encounter during use, as well as regular follow-up visits and maintenance services to ensure the long-term stability of the safety mat system.

Advantages of Customized Solutions

Customized safety mat solutions offer several advantages to businesses:

◾ Specific Needs Fulfillment: Every business has unique safety requirements. Customized solutions ensure that safety mats fully meet the specific needs of the environment and operational processes.

◾ Improved Compatibility: Customized safety mats can seamlessly integrate with existing equipment and systems without the need for extensive modifications to current facilities.

◾ Enhanced Functionality: Customized solutions can incorporate additional features as needed, such as pressure sensitivity levels and signal output types, to accommodate complex safety requirements.

◾ Cost-Effectiveness: While customized products may have a higher initial investment, they provide better performance and longer service life in the long run, reducing total ownership costs.

◾ Enhanced Brand Image: By offering customized solutions, companies can demonstrate their commitment to safety and quality, enhancing brand image and market competitiveness.

◾ Flexibility and Scalability: Customized safety mats can be adjusted and expanded to accommodate future needs, maintaining long-term applicability.

◾ Customer Service: Customized solutions often come with more personalized customer service, including design consultations, technical support, and after-sales service, ensuring customers receive comprehensive support during use.

Recommended Pressure-Sensitive Devices

Replacement for ABB ASK-Series Safety Mat | ASO Safety Solutions SENTIR mat Safety Mat | BBC BIRCHER ESM-52 Series Safety Mat | Mayser SM/SM8/SM11 Series Safety Mat | OMRON UMA Series Safety Mat | Rockwell Automation 440F Series Safety Mat | Schmersal SMS Series Safety Mat

FAQs About Safety Mats

How does a safety mat work?

Safety mats operate using built-in pressure sensors. When a person or object stands on the mat, the pressure sensors detect the change in weight and send a signal to the connected control unit via a cable. Upon receiving the signal, the control unit triggers pre-set safety measures, such as stopping the machine or sounding an alarm, to ensure the safety of the operator.

In what situations are safety mats applicable?

Safety mats are suitable for various industrial environments, especially in situations where it is necessary to prevent personnel from entering hazardous areas. For example, they can be used to protect machinery operation areas, automated production lines, stamping machines, injection molding machines, and robotic workstations. Additionally, they are applicable in areas where it is necessary to prevent forklifts and other industrial vehicles from entering, such as warehouses and loading docks.

What are the maintenance requirements for safety mats?

The maintenance of safety mats is relatively simple but requires regular checks to ensure they are functioning correctly. This includes inspecting the mat for wear, tears, or damage, and ensuring that the sensors and cables are intact. The mat should also be cleaned regularly to prevent dust and debris from affecting sensor sensitivity. If the mat has been compressed by heavy objects or exposed to harsh environments for extended periods, more frequent checks and maintenance may be necessary. If the mat malfunctions, it should be replaced promptly to ensure the effectiveness of the safety system.

Disclaimer: The brands and specifications shown on this page are for product comparison and selection purposes only. Our safety mats are manufactured by DADISICK and are not official products of the listed brands. DADISICK offers replacements compatible with these brands' products. We do not own the rights to any of the mentioned brands. If you need to purchase official brand products, please contact the brand official representative.